Wheel (Bucket) Sand Washer

High sand washing efficiency

Long service life

Security and stability

Low power consumption

High level of automation

Large processing capacity

Product Introduction

XSD series wheel sand washer is developed integrating domestic and foreign technologies, tailored to the actual situation of the sand and gravel industry. It serves as a bucket type sand washing equipment matched with sand making machines, offering the triple functions of cleaning, dewatering and gradation. Widely applicable for washing, gradation and impurity removal of fine grained and coarse grained materials in the fields of metallurgy, construction materials and hydropower, and it is suitable for construction sand, and road coating sand and gravel.

Applicable materials

Mechanic sand

River pebbles

Granite

Natural sand

Limestone

River sand

Quartz sand

Basalt

Product Performance

Compact and reasonable structure effectively reduces the floor area.

The isolation design of bearings from water and sand helps to prevent damage of bearing caused by soaking in water, sand, and pollutants, reducing the failure rate.

The optimized design of transmission part simplifies on-site installation.

Professionally designed stock guide rails facilitate material excavation and discharge. The reasonable sieve mesh design combined with optimized bucket-wheel rotary speed ensures maximum discharge of water and impurities.

The loss of fine sand and stone powder is minimal, and the gradation and fineness modules of washed construction sand meet standard requirements.

The reasonable design of discharge troughs and drainage outlets facilitates the discharge of materials and water.

The wheel sand washer has almost no wearing parts except for the sieve mesh, ensuring a long service life without the need for frequent maintenance.

With its large processing capacity, low power consumption, water saving features, and minimal environmental impact, it stands a green and eco-friendly solution.

Operation Principle

During operation, the motor drives the impeller to rotate slowly through triangle belt, reducer and gear wheel after deceleration. Sand and gravel enter the washing tank from the feeding trough, where they roll and grind each other driven by the impeller, effectively removing impurities from the surface. Simultaneously, the water vapor layer covering sand particle is destroyed to facilitate dehydration. At the same time, water is added to form a strong water flow, promptly removing impurities and small objects with specific gravity, which are then discharged from outlet of washing tank to complete the cleaning process. The clean sand and gravel are taken away by the blades and finally poured into the discharge trough from the rotating impeller to complete the cleaning process.

Technical parameter

| Model | XLD2600 | XLD2800 | XLD3200 | XLD3600 |

|---|---|---|---|---|

| Diameter of wheel (mm) | 2600 | 2800 | 3200 | 3600 |

| Max. feeding size (mm) | ≤10 | |||

| Width of wheel-bucket (mm) | 985×2 | |||

| Quantity of wheel-bucket | 32 | |||

| Rotation speed (r/m) | 1.2 | |||

| Capacity (t/h) | 20~50 | 30~70 | 50~100 | 80~150 |

| Motor type | Y160L-8 | Y180L-8 | Y200L-8 | Y225S-8 |

| Power (kw) | 7.5 | 11 | 15 | 18.5 |

| Water consumption (t/h) | 10~30 | 10~40 | 10~60 | 20~110 |

| Weight (t) | 2.7 | 5.5 | 6.1 | 9.3 |

| Overall dimension (L×W×H) (mm) | 3254×2060×2622 | 3810×2820×2883 | 3810×2820×3083 | 4456×2479×3688 |

Product Show

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.

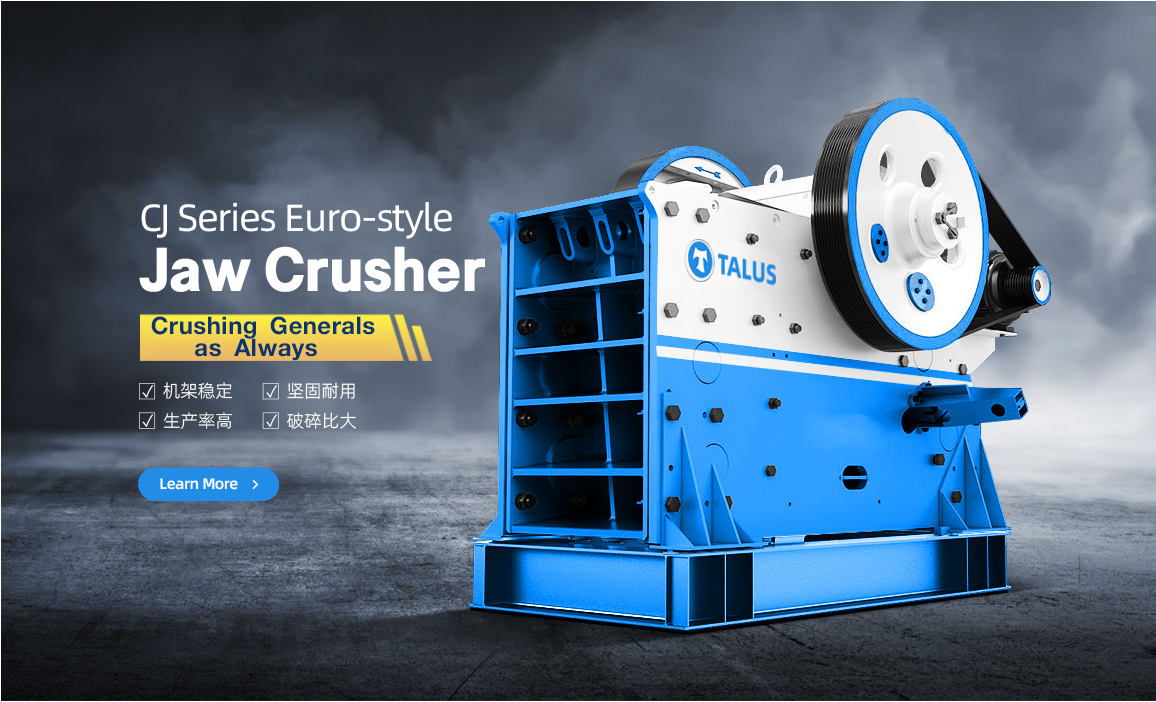

More Device Recommendation

Perhaps you are still in need of further device recommendations

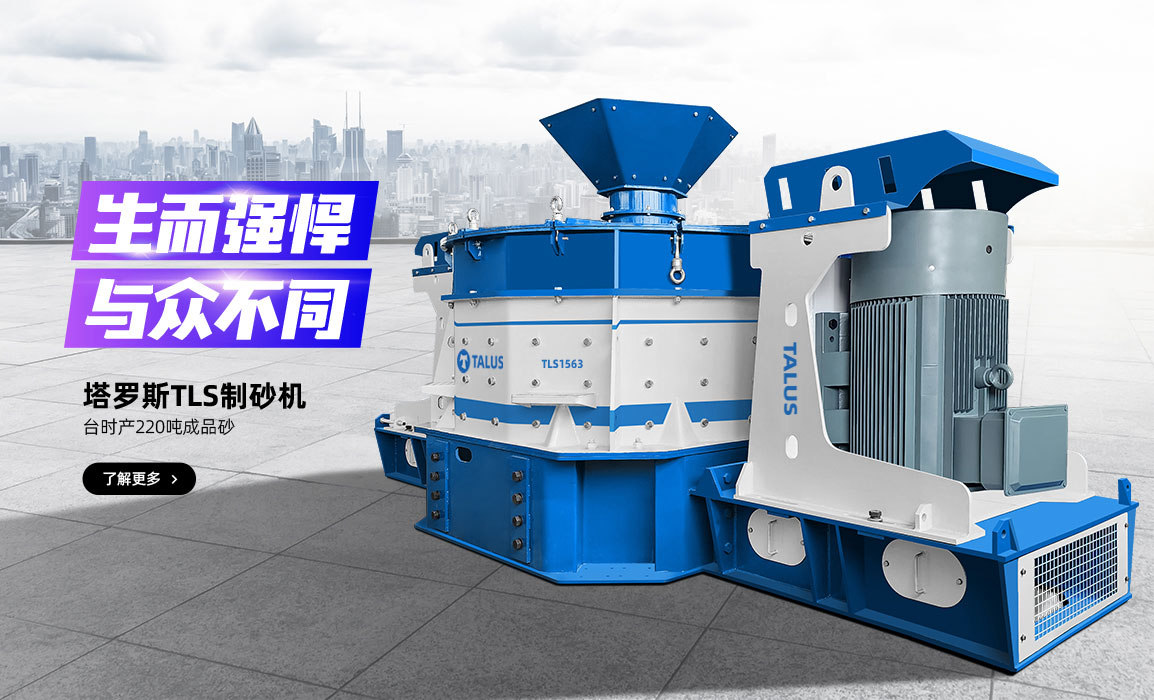

CLV Vertical Shaft Impact Sand Making Machine

PFL Vertical Compound Sand Making Machine

Talus Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

Please kindly submit your request for a comprehensive product offer