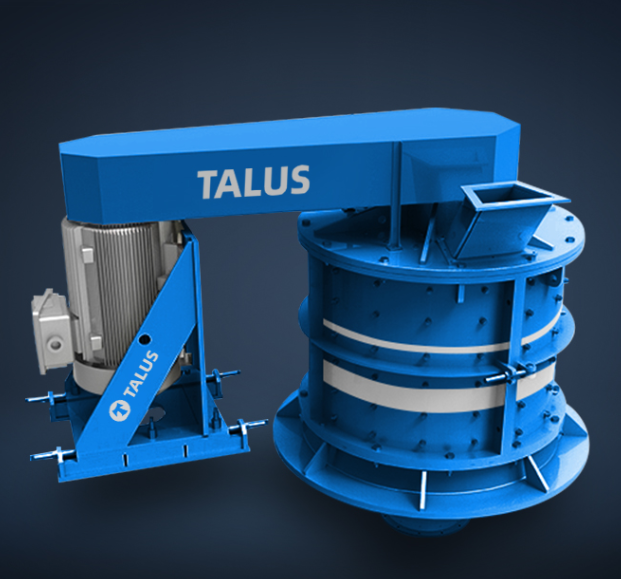

When it comes to sand making for dry mortar, the use of a composite sand maker is generally more common and suitable. The composite sand maker can break the raw materials into required particle size and shape through the dual effects of impact and friction to meet the requirements of dry mortar. The impact sand maker, on the other hand, can produce sand particle with better shape, and reputable manufacturers are gradually adopting this technology.

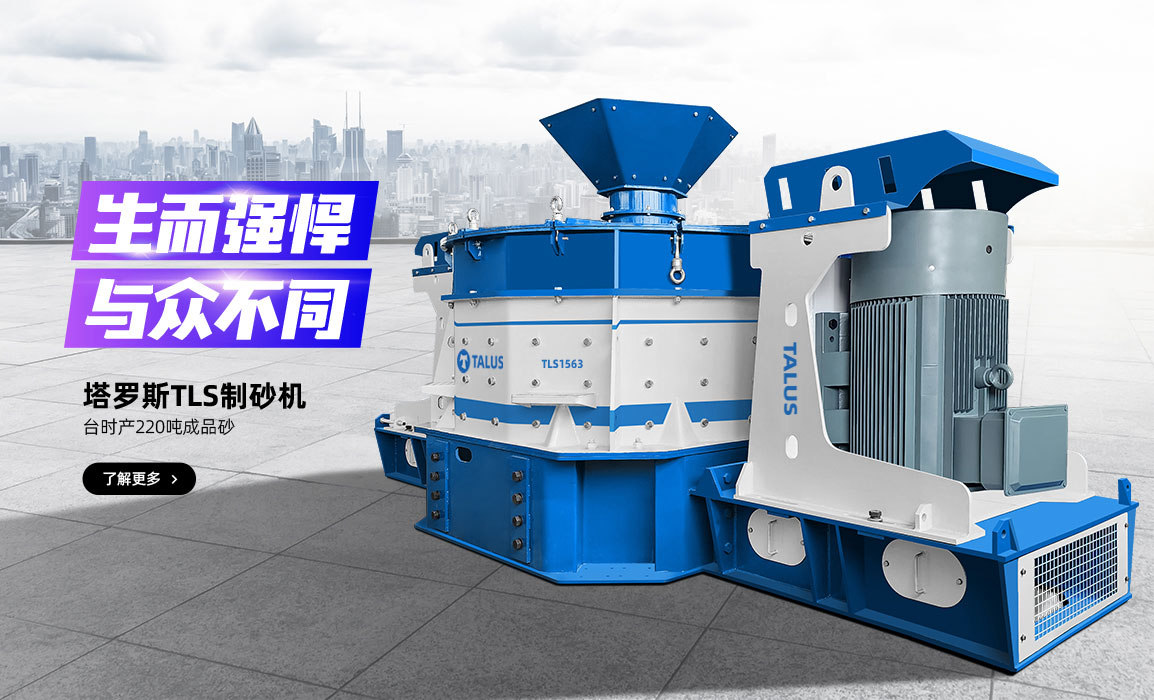

Dry mortar sand maker - Talus sand maker

As for the sand standards for dry mortar, they may vary depending on different countries, regions and application fields. However, there are some common standards to consider:

1. Sand Particle Size: The sand particle size should be uniform, and the proportion of sand particles of different particle sizes should meet the requirements.

2. Mud Content of Sand: The sand should have a controlled contend of mud, clay, and other impurities to ensure its purity.

3. Moisture Content of Sand: The sand should have a moderate moisture content, neither too wet nor too dry.

4. Chemical Composition of Sand: The sand’s chemical composition should comply with the requirements of dry mortar formula to ensure compatibility and performance with other materials.

To obtain more accurate information on specific sand standards for dry mortar, it is recommended to refer to relevant industry standards or consult professional organizations or suppliers for more accurate information based on actual conditions and project requirements. Reputable dry mortar companies usually use a new type of vertical shaft impact sand making machine - such as the Talus sand maker, for dry mortar sand making. This powerful equipment can produce 220 tons of finished sand per hour with better sand particle shape.