The following sensors can be used to monitor the operation status and working environment of the sand maker:

1. Temperature sensor: Used to monitor the temperature of various parts of the sand maker, such as the engine, bearings, and lubrication system. This can help detect overheating or low-temperature situations and prevent equipment malfunctions.

2. Pressure sensor: Used to monitor the pressure of the sand maker, such as in the crushing cavity, conveyor belt, and conveying pipelines. This can help detect abnormal or excessively high pressure situations and take timely measures to ensure safe operation of the equipment.

3. Vibration sensor: Used to monitor the vibration of the sand making machine, such as in the vibrating screen and crushing cavity. This can help detect the vibration condition of the equipment, prevent excessive vibration that may cause equipment damage or instability.

4. Flow sensor: Used to monitor the material flow of the sand making machine, such as at the feeding inlet and discharge outlet. This can help control the supply and discharge of materials, ensuring the normal operation and product quality of the sand maker.

5. Liquid level sensor: Used to monitor the liquid level of the lubrication system of the sand maker, such as in the lubrication oil tank and lubrication pipelines. This can help timely detect the supply of lubricating oil, ensuring the lubrication and cooling effect of the equipment.

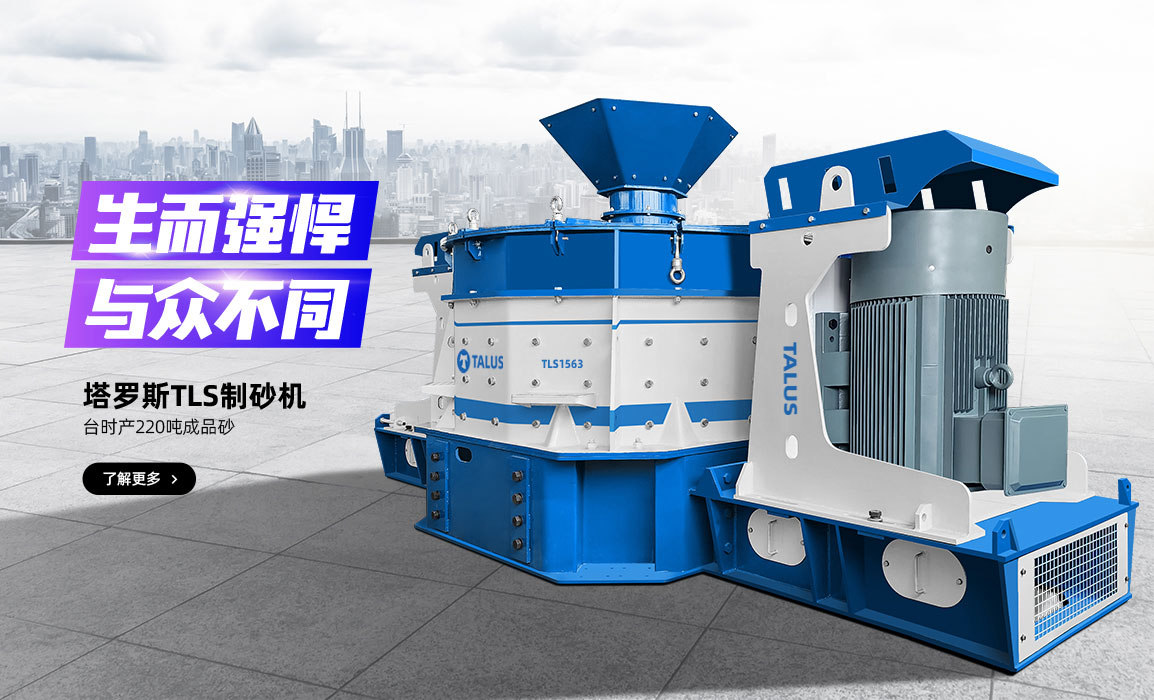

The data from these sensors can be monitored and analyzed in real-time through an intelligent control system, enabling precise monitoring and control of the operation status and working environment of the sand maker. Choose the Talus sand maker, a new type of vertical impact sand making machine, for a more powerful sand making experience!