It is worth noting that the rotation speed of the crusher has an impact on production. As the mechanism sand market is booming and attracting many investors, the investment in sand production plants cannot be separated from stone crushing equipment. When investing in stone crushers, the relevant personnel of the manufacturing company will provide users with detailed introductions to the technical parameters of the equipment. When viewing the parameters of the crusher, we will find that the rotor speed of the crusher varies greatly. So, what should be the general speed of the crusher? In the following, we will take the hammer crusher as an example to explain the issue of crusher speed in detail.

Different crusher models have different speeds. In hammer crushers, we can see that the larger the model, the slower the rotor speed. The inverse relationship between the rotor speed and the crusher model is because different crushers crush materials of different particle sizes.

The size and weight of the hammer heads of the hammer crusher are also different.

The larger the model of the crusher, the larger the crushed material, the heavier the hammer head, and the larger the volume. It has a large linear velocity and inertia at low speed, which is already easy when crushing the material; the smaller the model of the crusher, the smaller the crushed material, the smaller the hammer head, and the lighter the weight. In order to achieve the purpose of crushing the material, the hammer head needs to have kinetic energy, so the rotor speed of the smaller model crusher needs to be higher, so that the hammer crusher can have impact force when crushing the stone material.

The impact of crusher speed on production

Crusher manufacturers have found through multiple experiments that the rotor speed has a certain impact on the production capacity of the crusher equipment. The reason why the speed of the crusher is getting lower and lower is because when crushing the stone material, the stone material falls onto the hammer head of the crusher, which allows the hammer head to work on the stone material and crush it; if the rotor speed is too high, the stone material cannot fall onto the hammer head of the crusher and will be bounced off. In this case, the stone material cannot be worked on, which greatly reduces the efficiency of the crusher equipment, and high-speed rotation will cause the hammer head to grind the stone material, resulting in excessive crushing of the stone material, which is not conducive to equipment production.

What is the general speed of the crusher?

The speed of the crusher is influenced by various factors, generally including the hardness of the materials to be crushed, the crushing capacity of the crusher, the structure, power, and environment. It needs to be determined based on specific circumstances, and it is recommended to have a process. Don't pursue too high or too low speed. The rotor speed of the hammer crusher is a good example. Too low rotor speed cannot achieve the purpose of crushing the stone material, and too high rotor speed cannot crush the stone material well. Only by controlling the speed within a certain range can the crusher equipment achieve high working efficiency.

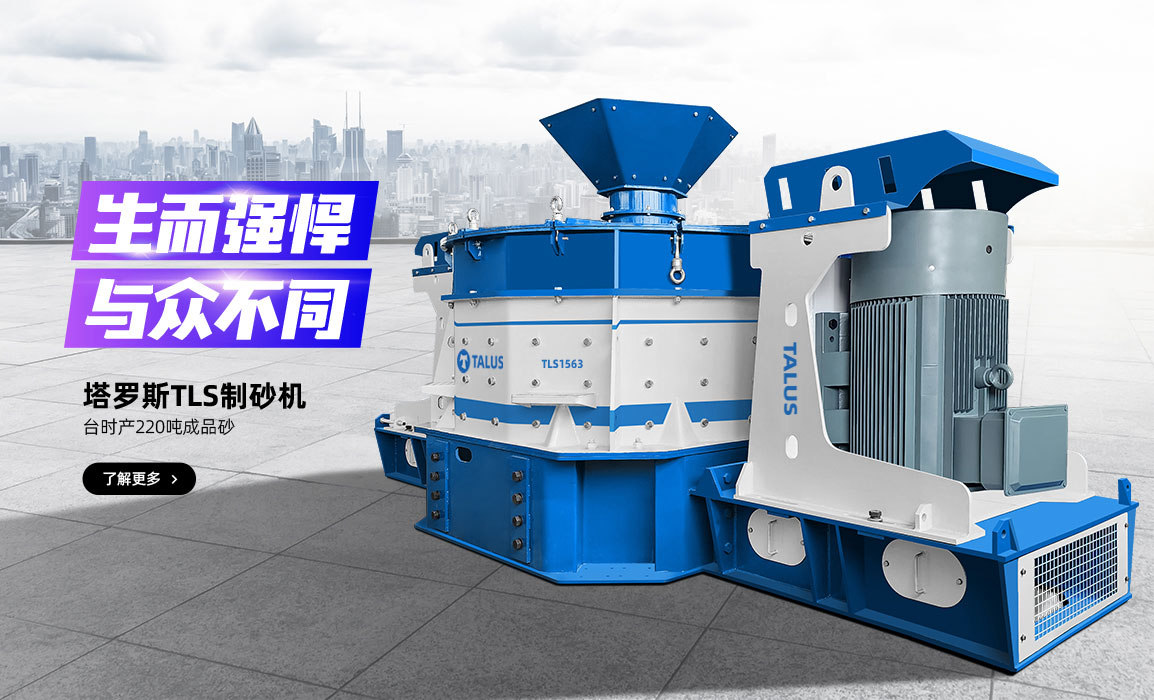

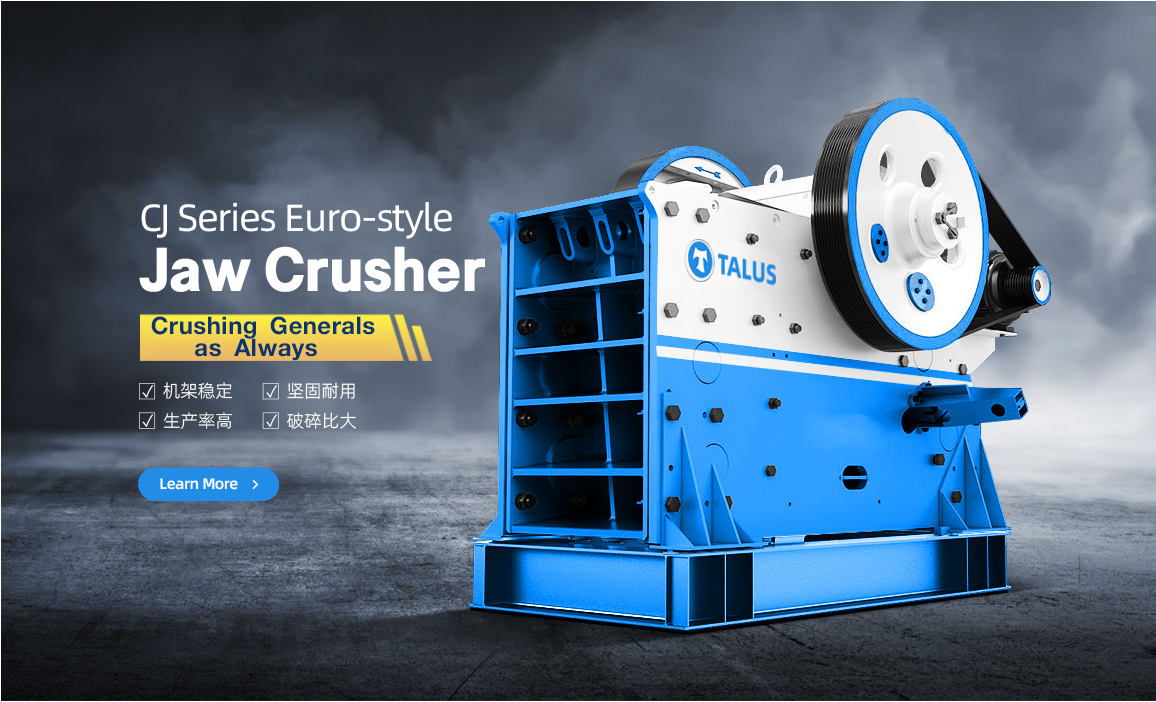

Talus Equipment focuses on the field of mining crushing and screening, as well as sand-making equipment, providing cost-effective crushing and screening solutions, mechanism sand equipment, and high-grade sand and gravel aggregate for large-scale engineering projects such as highways, chemical industry, railways, hydropower, etc.

If you want to learn more about crushing and sand making equipment, you can consult our online customer service. If you have any requirements for production lines, we will arrange a professional project manager to provide detailed answers and equipment configuration.