Among the building materials, bluestone and limestone are high-quality construction materials. After crushing and processing, they have high market value and can be widely used in building materials, plastics, paper making, coatings, and ink departments. So can the single-cylinder cone crusher be used for crushing these materials? What are the advantages?

First of all, there is no problem in processing bluestone with a single-cylinder cone crusher. Let's analyze these issues briefly.

1. Crushing capacity:

This equipment has various types of crushing cavity that can be freely adjusted, with medium, fine, and ultra-fine crushing functions, meeting the needs of a wide range of users.

2. Functional analysis:

The single-cylinder cone crusher uses the principle of laminated crushing to achieve the purpose of crushing stone materials. Various processes of crushing medium and high hardness stone materials can be described as easy. The Mohs hardness of limestone is generally around 3, which belongs to medium hardness stone materials.

3. Model Selection

The single-cylinder cone crusher has two models: medium crushing and fine crushing. Each model has multiple chamber types to choose from and can also adapt to different production processes and conditions through eccentric distance adjustment. By adjusting the speed of the transmission shaft, the product grading can also be adjusted, maximizing the value of the equipment. The eccentricity for medium crushing operation is between 20-40mm and the discharge size is between 25-45mm. The eccentricity for fine crushing operation is between 20-40mm and the passing size of the discharge opening is between 8-35mm.

4. Equipment Advantages

The basic criteria for purchasing a crusher in modern limestone processing plants are environmental protection and high efficiency. The single-cylinder cone crusher integrates advanced crushing production technology, intelligent structural design, dust removal, noise reduction, high output, and large processing capacity, making it the ideal choice for limestone crushing.

5. Pricing

If you are satisfied with both the particle size and production capacity of the crushing, then how much does it cost to invest in such equipment? Compared to other crushers, this equipment has a more sophisticated structure and process, so the price will be higher. Different crushing equipment should be selected based on different crushing functions.

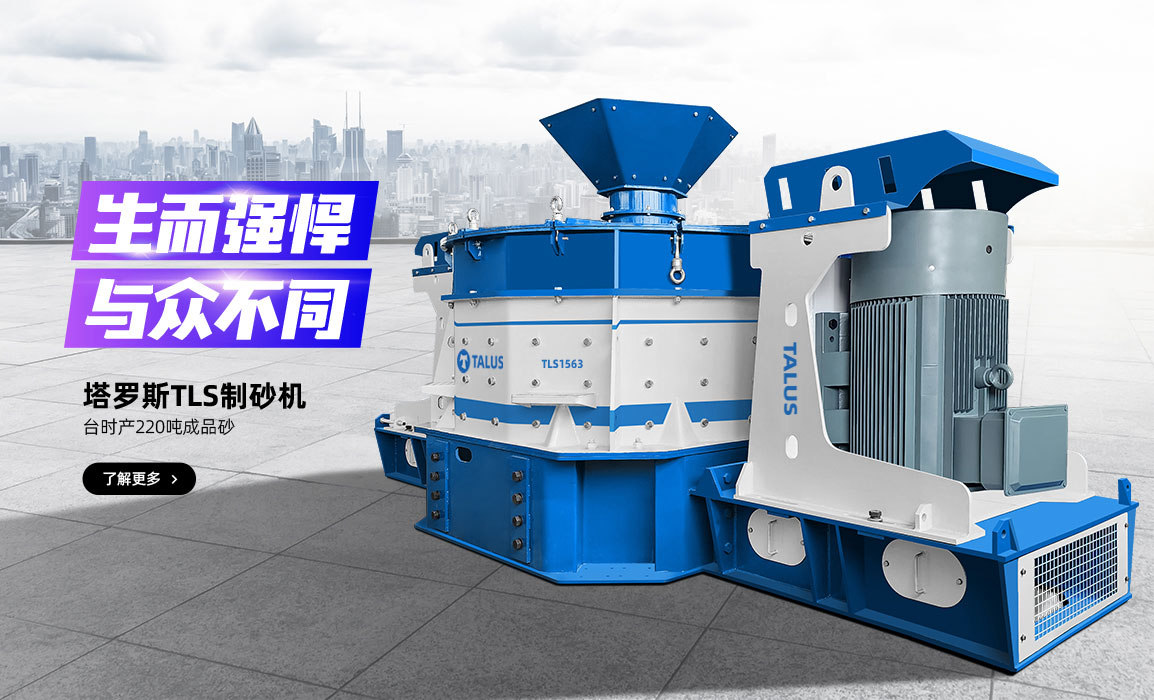

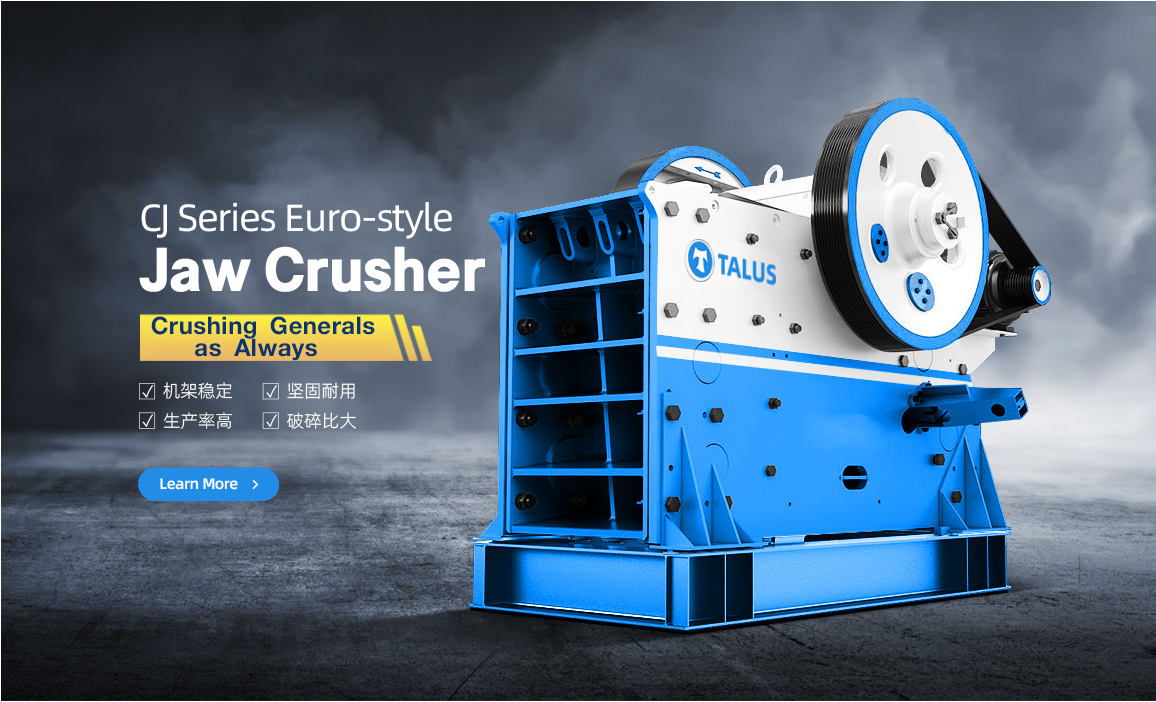

Talus Equipment focuses on the field of mining crushing and screening, as well as sand-making equipment, providing cost-effective crushing and screening solutions, mechanism sand equipment, and high-grade sand and gravel aggregate for large-scale engineering projects such as highways, chemical industry, railways, hydropower, etc.

If you want to learn more about crushing and sand making equipment, you can consult our online customer service. If you have any requirements for production lines, we will arrange a professional project manager to provide detailed answers and equipment configuration.