Sand and gravel aggregates are one of the essential building materials and a necessity for engineering construction. Based on recent surveys of the major sand and gravel markets in China and infrastructure projects, the prospects for infrastructure construction are still strong, and industry insiders have high expectations for infrastructure investment. There are still tremendous development opportunities for the sand and gravel industry in the next year.

However, in recent years, there have been serious pollution problems in sand and gravel plants, and many of them have been shut down. Mechanism sand supply is in short supply. Under strict environmental protection regulations, should we shy away from such good business opportunities? Sand and gravel plants need to pay attention to two aspects when designing sand production lines for long-term and stable development. Firstly, ensure the quality of the finished sand and gravel to enhance competitiveness and profitability. Secondly, meet environmental standards and eliminate problems of dust, noise, and wastewater pollution to comply with strict environmental regulations.

Control of Mechanic Sand Quality

The quality indicators of mechanic sand mainly include particle size distribution (fineness modulus), clay content, stone powder content (methylene blue test), moisture content, and crushing index. Based on these requirements, the quality of mechanic sand can be controlled by selecting appropriate raw materials and equipment to achieve high-quality mechanic sand.

1. Selection of Raw Materials

When producing mechanic sand, there are requirements for raw materials:

- The compressive strength of the raw material for mechanic sand should be ≥80 MPa and should not have potential alkali-reactive aggregates. It is advisable to use clean, hard, and non-weak particle raw materials to meet the crushing index requirements.

- Avoid using mines with thick covering soil layers, high clay content in interlayers, and rock layers that are layered and fragmented to control the clay content.

- Choose raw materials with exposed rock layers. If there are covering soil layers or weathered layers, they should be promptly removed. Based on these requirements, it is recommended to use materials such as pebbles, river pebbles, limestone, granite, and basalt, which have stable performance, meet the hardness standards, have large reserves, are easy to mine, and have low costs.

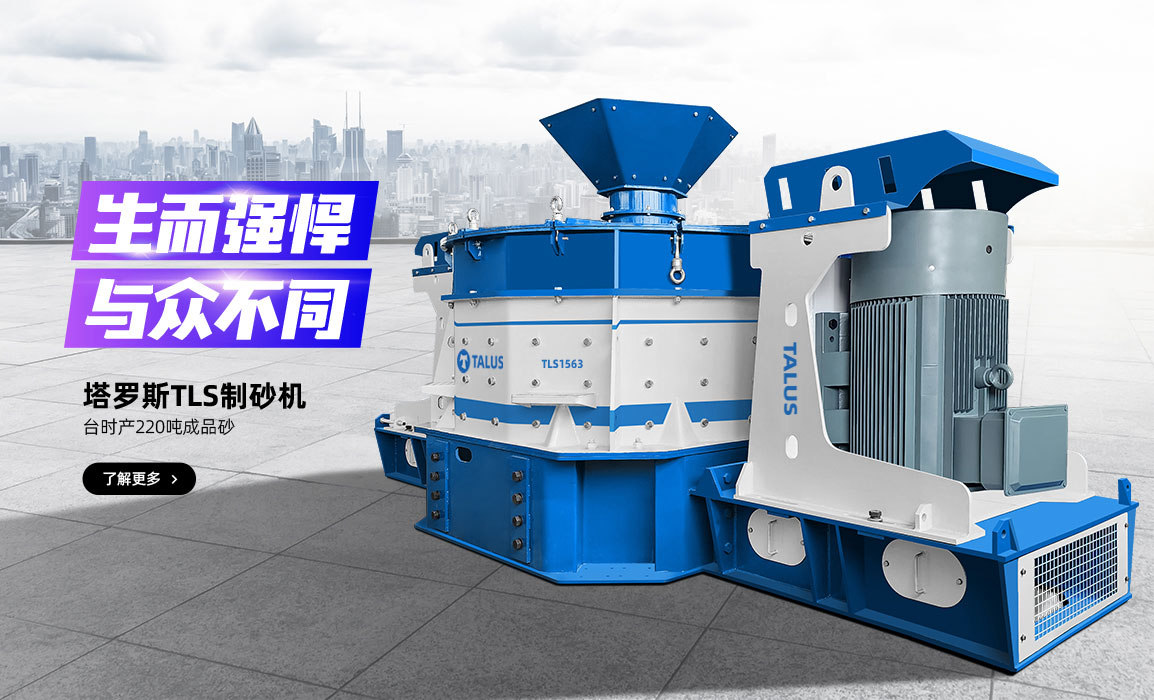

2. Selection of Sand Making Equipment

The finished mechanic sand is made by sand making machines. Choosing the right sand making machine can greatly improve the effect of sand production. It is recommended to use the ML series impact sand making machine, which has low dust pollution, low noise, and functions as both sand making and shaping. The discharge particle size can be adjusted, and the produced sand grains are round and evenly sized, meeting the standard of Grade I mechanic sand. It is recommended to control the feed particle size to around 30-50mm during production, as this will result in a better quality of the sand produced by the impact sand making machine.

Advantages of the LV series impact sand making machine:

- Sand Making and Shaping: The impeller cavity is deep, increasing the throughput of stones by 30%. It has shaping effects, producing well-shaped sand with reasonable particle size distribution and adjustable fineness modules.

- Durability and Easy Maintenance: The core components are carefully crafted, making them more durable and extending their lifespan by 1.5-3 times. The hydraulic cover can be opened, making it more convenient for users to inspect and repair, with simple daily maintenance.

- Multiple Crushing Standards: It adopts the principle of "stone on stone" or "stone on iron" for crushing, occupying a small area and making sand production simple. The combination-type discharge head allows for easy replacement of worn parts, reducing operating costs by 30%.

- Environmentally Friendly and Energy-saving: The internal airflow in the vortex chamber circulates, resulting in less dust and low noise. It also uses branded motors with sufficient kinetic energy, making it more energy-efficient. It is also necessary to equip a sand washing machine to clean the sand and reduce the content of fines, controlling it between 3% and 7%. After washing, a combination of dewatering screening and natural stacking is used to control the moisture content between 3% and 5%. Only after these operations can high-quality mechanic sand be obtained.

Environmental Design of the Mechanic Sand Production Line

1. Dust Suppression

The dust produced during the mechanism sand production process is generally referred to as organized dust, while the secondary dust caused by open-air stockpiling and transportation is generally referred to as unorganized dust. The national regulations require the dust emission concentration to be lower than 30㎎/m³. The specific control measures are as follows:

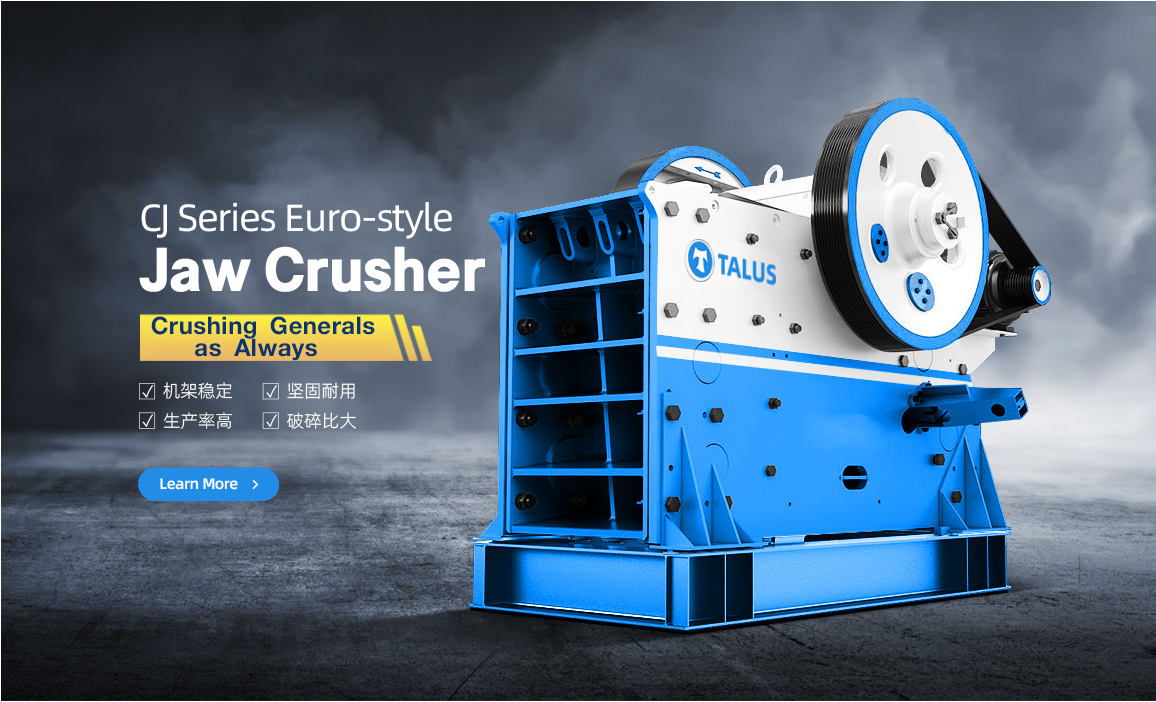

1) Choose equipment with less dust and good sealing performance, and install a high-pressure spray system at the jaw crusher and vibrating feeder. Install a bag dust collector at the discharge position of the production line.

2) Reduce material drop and control conveying speed in the material transfer process to minimize dust emission.

3) Take measures such as spraying humidifying and sealing storage during material handling, loading, and stacking to reduce dust emission.

2. Noise Control

The national regulations for industrial noise in the industrial area are below 65dB(A) during the day and below 55dB(A) at night. To control noise, start with the crushing and screening equipment and choose new process equipment with low noise as much as possible. Reduce noise from the source by installing mufflers and soundproof enclosures on the equipment.

3. Wastewater Treatment

The wastewater generated during the sand production process is mainly from sand washing. A sedimentation tank can be constructed for treatment. Install a sludge hopper at the inlet of the sedimentation tank. The wastewater flows in from one end of the sedimentation tank and out from the other end, filtering out the sludge. The filtered water can be reused for sand washing, achieving wastewater recycling and saving water resources. The sedimented sludge and waste soil can also be used for mine site reclamation.

By designing the sand and gravel production line according to the above methods, the produced mechanism sand has excellent quality and broad sales channels. The entire production process is environmentally friendly, achieving both economic benefits and environmental protection.

If you are interested in better crushing and sand making machines, please contact us at Henan Talus Equipment sales hotline: [+86-400-659-6555].