How to design the main shaft of a new sand making machine to prevent breakage? How to prevent the main shaft from breaking during the use of the sand making machine? To design a main shaft that is not easily prone to breakage in a new sand making machine, the following points can be considered:

1. Material selection: Choose high-strength and high-toughness materials for the manufacturing of the main shaft, such as high-quality alloy steel or special alloy steel. These materials have high strength and toughness, providing better resistance to breakage.

2. Structural design: The structural design of the main shaft should consider uniform stress distribution and pressure balance. Reasonable shaft diameter and axial strength distribution, as well as appropriate thinning treatment, can improve the bearing capacity and resistance to breakage of the main shaft.

3. Lubrication and maintenance: Proper lubrication and maintenance are crucial to reduce the risk of main shaft breakage. Regular inspection and replacement of lubricating oil, maintaining proper lubrication and cooling, can reduce wear and heat accumulation of the main shaft.

4. Avoid overloading: During use, avoid operating under overload conditions to prevent the main shaft from bearing excessive load and impact force. Control the feed rate and discharge particle size properly to ensure that the main shaft operates within the normal working range.

5. Regular inspection: Regularly inspect the working condition and wear of the main shaft, and promptly identify and address any issues that may cause shaft fractures, such as cracks and wear.

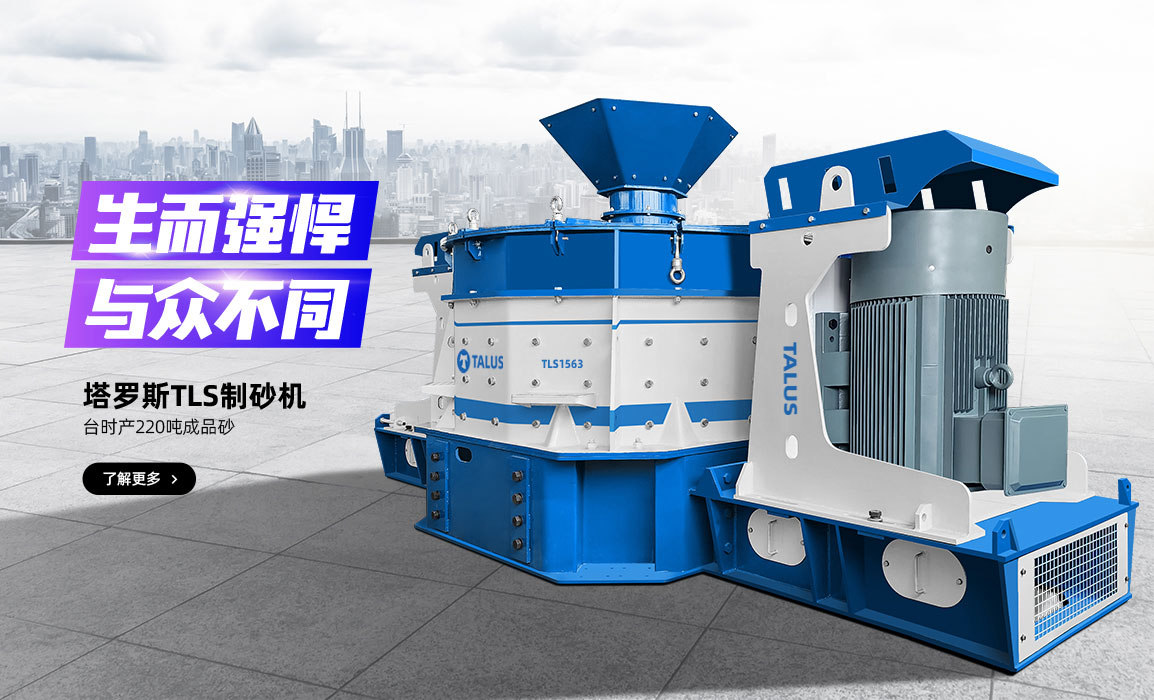

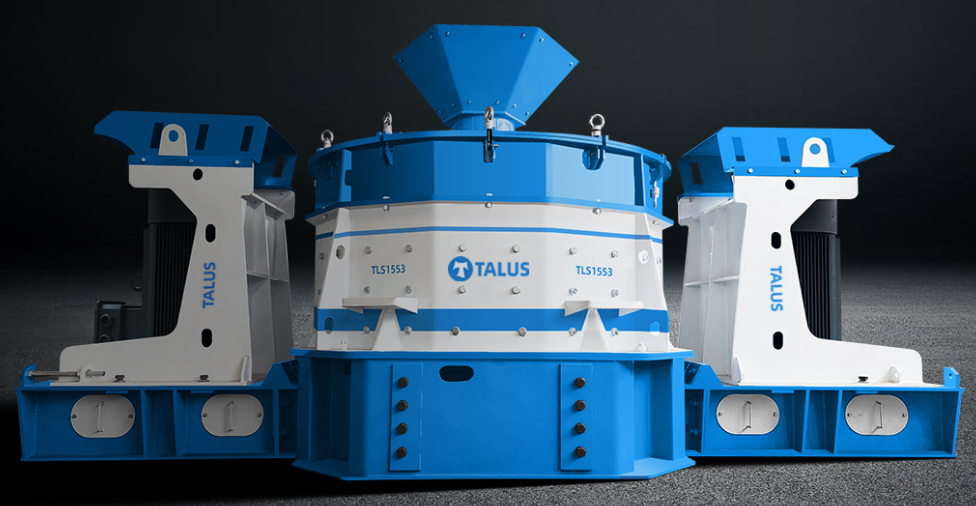

In conclusion, by selecting appropriate materials, optimizing the structural design, and performing regular lubrication and maintenance while avoiding overload operations, the risk of main shaft fractures can be reduced, and the lifespan of the sand making machine can be extended. The Talus sand maker features a reinforced main shaft, which is upgraded based on traditional VSI sand makers and advanced European sand making machines. The optimized design of the central shaft module includes a specially designed dust-proof and sealing structure, along with imported bearings from the United States, providing stronger load-bearing capacity. This resolves the risk of main shaft fractures or failures during high-load operations commonly associated with traditional VSI sand makers, ensuring more stable and secure machine operation. Choose the Talus sand making machine for a high-quality sand making solution!