By optimizing the materials and structural design, the lifespan of a sand making machine can be improved. The specific methods include:

1. Selecting high-strength materials: Choose high-strength materials for the main components of the sand making machine to enhance its compressive strength, wear resistance, and corrosion resistance. Common materials include high-hardness alloys, wear-resistant steel, and stainless steel.

2. Adding protective measures: Add protective materials or coatings to vulnerable areas to reduce wear and extend the lifespan. For example, adding wear-resistant lining plates to the crushing chamber and feed opening can improve their wear resistance.

3. Optimizing the structural design: Reduce the stress and wear on vulnerable parts through rational structural design. For example, using proper stress distribution and mechanical principles can reduce stress concentration and wear on components.

4. Strengthening the connection methods: Choose reliable connection methods such as welding and bolt connections to ensure secure connections between components, reducing looseness and wear.

5. Enhancing lubrication and cooling: Design lubrication and cooling systems to ensure proper lubrication and temperature during operation, reducing wear and thermal damage.

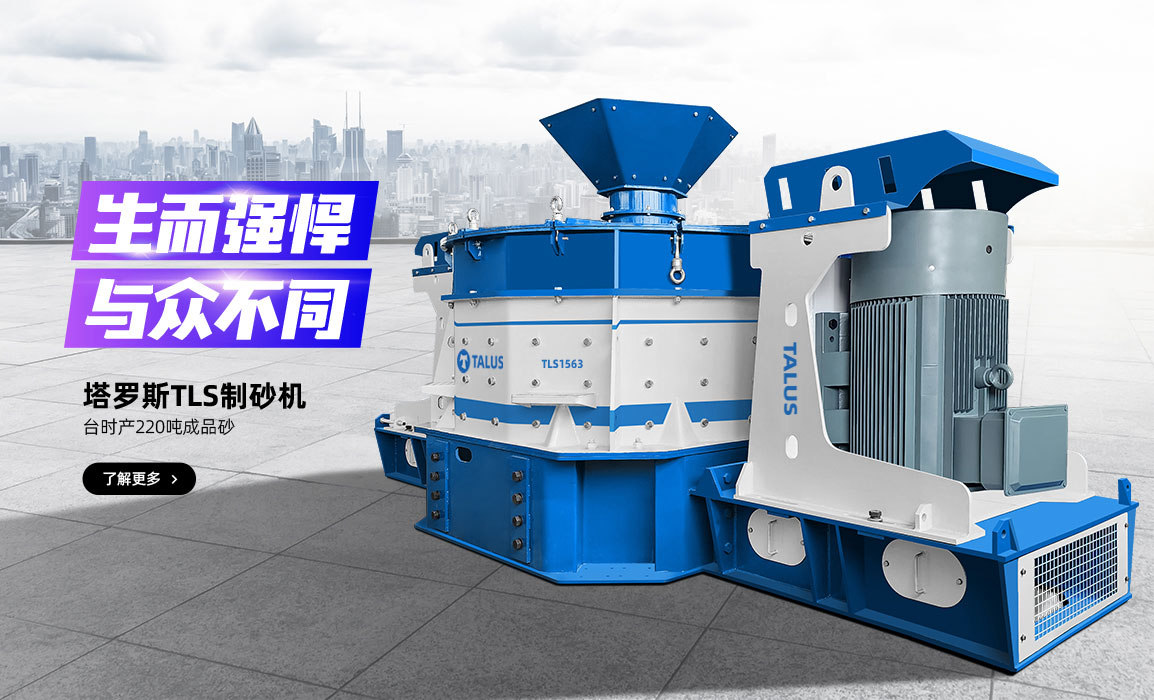

By implementing these optimization measures, the materials and structural design of a sand making machine can be more durable and reliable, extending its lifespan, reducing maintenance costs, and improving production efficiency. Choose Talus sand maker for a powerful and innovative vertical shaft impact crusher!