PC/PCZ Series Heavy Hammer Crusher

High Crushing Ratio

High Production Efficiency

Safe and Stable

High Comprehensive Benefits

Easy Operation and Maintenance

Good Granularity of Finished Product

Product Introduction

The PCZ Series Heavy Hammer Crusher has characteristics of special structure, simple operation, energy saving, good granularity of finished product, adjustable discharging particle size, and costs saving, etc. The appearance and structure of the heavy hammer crusher and the impact crusher are basically the same, the only difference is the form of the rotor. The rotor of the heavy hammer crusher uses independent hammer heads that can rotate around the hammer shaft, while the rotor of the impact crusher uses high-chromium plate hammers. The heavy hammer crusher has large weight per hammer head, reasonable rotor speed, and large hammer head inertia, which can achieve the crushing effect of large feeding particle size and small discharging particle size. It can directly crush materials with a particle size of 600-1200mm to below 25mm.

Performance advantages

Large crushing ratio, Uniform particle shape

Low powder output!

① Large feeding particle size (up to 1200mm), high crushing ratio, high output (single machine output up to 2500 tons).

② Uniform finished product shape. Less flake, low powder output, meeting excellent sand and gravel standards.

② Uniform finished product shape. Less flake, low powder output, meeting excellent sand and gravel standards.

The practical parts of the machine are made of high-quality materials

Which have a longer service life!

① The hammer head is made of high-chromium alloy, which more than doubles the service life of ordinary high-manganese alloy hammer heads.

② The impact plate is made of high-manganese castings and is quenched and strengthened, further improving its practicality and impact resistance.

② The impact plate is made of high-manganese castings and is quenched and strengthened, further improving its practicality and impact resistance.

Dual-use for dry and wet materials

Green and environmentally friendly!

① It can crush both dry and wet materials.

② Water spray can be added during crushing to reduce dust pollution, protect the health of workers and the environment, and promote green and environmental protection.

② Water spray can be added during crushing to reduce dust pollution, protect the health of workers and the environment, and promote green and environmental protection.

Reasonable structural design

Better equipment!

① The grate-less design, change the previous phenomenon of grate bars controlling the discharging, and directly control the discharge blockage in the crushing chamber with the adjusting plate.

② Volute design with reinforced ribbed back can withstand strong impact forces internally and externally, making the machine sturdy and resistant to impact without deformation.

② Volute design with reinforced ribbed back can withstand strong impact forces internally and externally, making the machine sturdy and resistant to impact without deformation.

Short maintenance time, Low maintenance cost

Easy disassembly!

① Before the assembly of the rotor, static and dynamic balance tests are conducted. The main shaft is processed with excellent forgings and adopts the expansion sleeve tightening connection method to make the equipment operate more reliably.

② The overload protection and tramp iron detection devices have been optimized. When the impact crusher exceeds its own load, this device can adjust the clearance between the impact plate and the discharging opening in time to prevent the equipment from stopping due to overload.

② The overload protection and tramp iron detection devices have been optimized. When the impact crusher exceeds its own load, this device can adjust the clearance between the impact plate and the discharging opening in time to prevent the equipment from stopping due to overload.

Working Principle

The finished product can be adjusted according to requirements, with various specifications such as coarse, medium, and fine, no flakes, no smooth bodies, and multi-angles and edges to ensure compressive strength. Especially suitable for dry highways, construction and large-scale engineering materials. This crusher eliminates the primary crushing process of the jaw crusher and becomes a new model that can crush large and small materials in one go. It has a large output, high efficiency, low power, saves manpower and material resources, and reduces the cost of crushing materials. The stone crushed by this machine not only has complete specifications, but is also uniform and clear. It is a substitute for the old-fashioned jaw crusher and plate hammer crusher.

Performance Parameters

The following product configurations are not necessarily factory standard configurations. Please consult us in detail when purchasing.

| Model | Rotor diameter × length (mm) | Feeding opening size (mm) | Feeding size (mm) | Production capacity (t/h) | Motor power (kw) | Overall dimension (L×W×H)(mm) |

|---|---|---|---|---|---|---|

| XGN-Z1310 | 1310×1050 | 890×1075 | ≤650 | 150-180 | 160 | 2950×2250×2495 |

| XGN-Z1512 | 1500×1160 | 1200×900 | ≤750 | 250-320 | 160×2 | 3260×2624×2750 |

| XGN-Z1513 | 1500×1350 | 1290×900 | ≤750 | 300-350 | 180×2 | 3260×2624×2750 |

| XGN-Z1615 | 1650×1452 | 1500×1200 | ≤1000 | 420-500 | 220×2 | 3667×2937×3436 |

| XGN-Z1818 | 1850×1800 | 1500×1280 | ≤1200 | 570-670 | 250×2 | 3680×3350×3515 |

| XGN-Z1620 | 1660×1900 | 2000×1200 | ≤1200 | 800-1000 | 400×2 | 3667×3200×3436 |

| XGN-Z1820 | 1800×1964 | 2000×1200 | ≤1200 | 1000-1200 | 450×2 | 3700×3270×3515 |

| XGN-Z2020 | 1920×2000 | 2010×1200 | ≤1500 | 1200-1600 | 450×2 | 4160×3920×3520 |

| XGN-Z2122 | 2130×2260 | 2240×1550 | ≤1500 | 1800-2200 | 1000 | 4990×4385×4360 |

| XGN-Z2225 | 2200×2485 | 2530×1560 | ≤1600 | 2000-3000 | 1250 | 4460×4565×4670 |

| XGN-Z3332 | 3300×3220 | 3300×1840 | ≤1800 | 4500-6000 | (1250kw-6)×2 | 6710×6122×6340 |

Product Show

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.

More Device Recommendation

Perhaps you are still in need of further device recommendations.

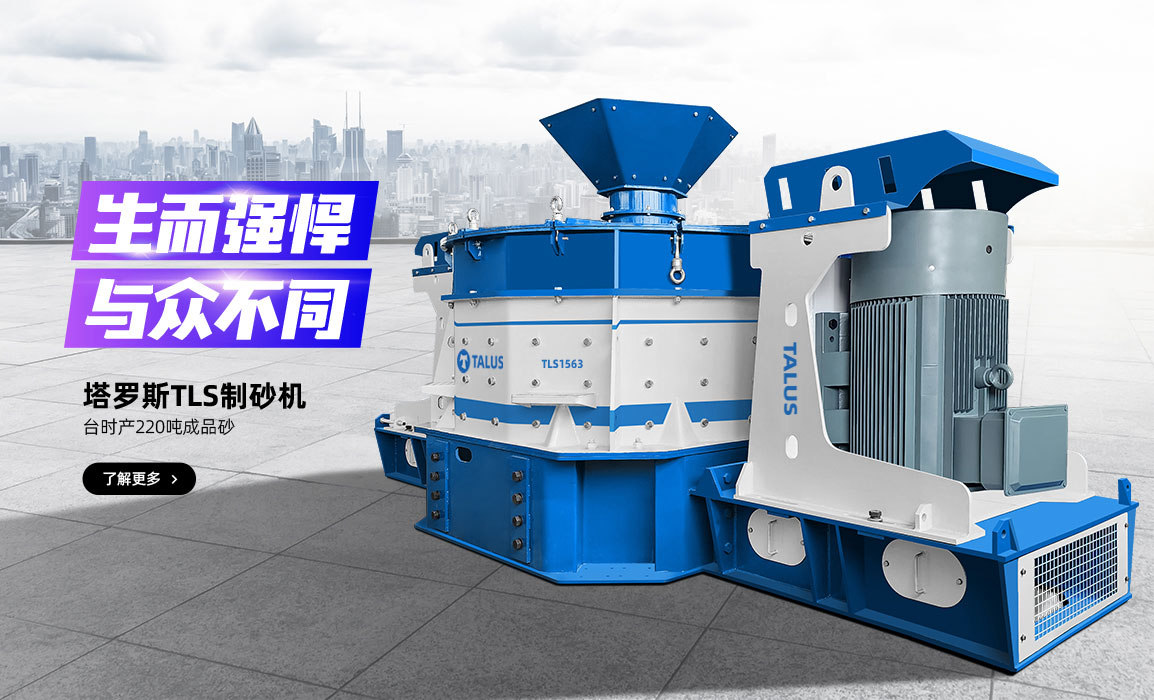

Talus Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

HP Multi Cylinder Hydraulic Cone Crusher

CLV Vertical Shaft Impact Sand Making Machine

PFL Vertical Compound Sand Making Machine

Inclined Vibrating Screen

Please submit your request for a detailed product offer