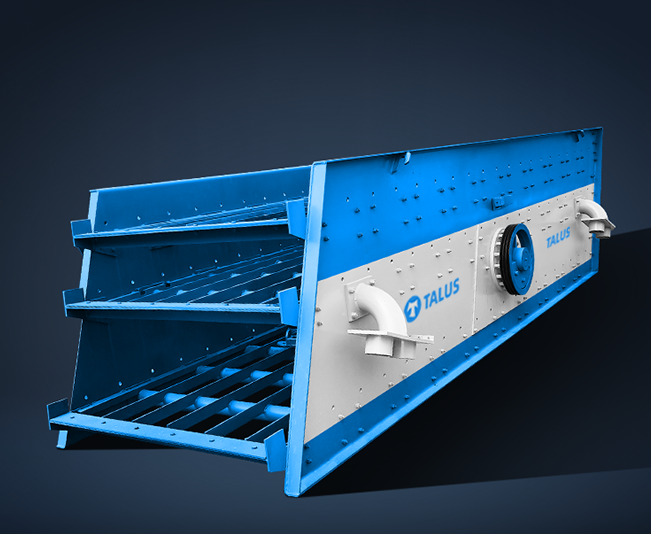

Is diluted oil lubrication or grease more effective for inclined vibrating screens? Both diluted oil and grease can be used as lubricants for inclined vibrating screens, but they may have different effects.

Diluted oil has lower viscosity and higher flowability, which allows it to penetrate better between the screen mesh and screen openings, reducing the possibility of bonding and blockage. The use of diluted oil can effectively reduce the clogging of openings, extend the life of the screen mesh, and improve screening efficiency.

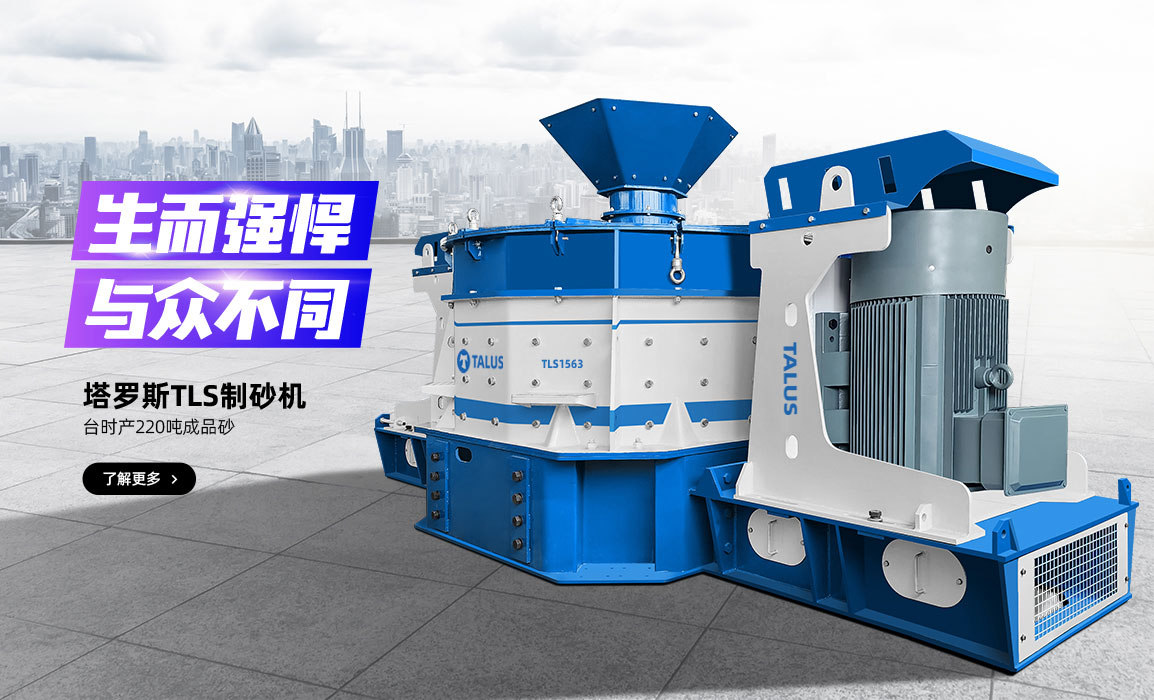

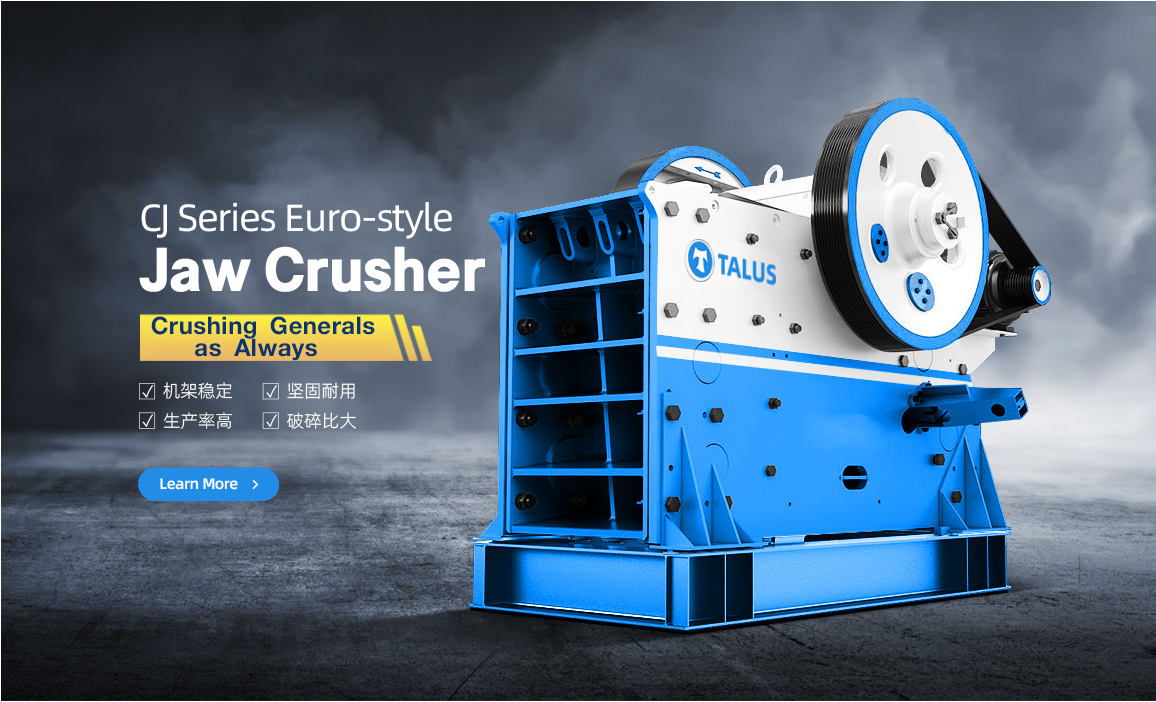

Grease typically has higher viscosity and better adhesion, providing a more long-lasting lubrication effect. The use of grease may reduce friction between screen meshes, thereby reducing the noise and vibration of the vibrating screen. Grease can also provide better sealing to prevent dust and impurities from entering the screening system. The choice between diluted oil and grease as lubricants depends on specific application needs and conditions. If better flowability and anti-blocking effects are required, diluted oil may be more suitable. If better adhesion, sealing, noise reduction, and vibration reduction are required, grease may be more suitable. The best choice should be evaluated and tested based on specific circumstances. Inclined vibrating screens are generally used as supporting products for crushers or sand makers. If you are looking for better sand making equipment, please consider Talus sand maker, a more powerful new vertical shaft impact sand maker!