Both the impact sand maker and composite sand maker are common sand making equipment, each with its own advantages and applicable scenarios.

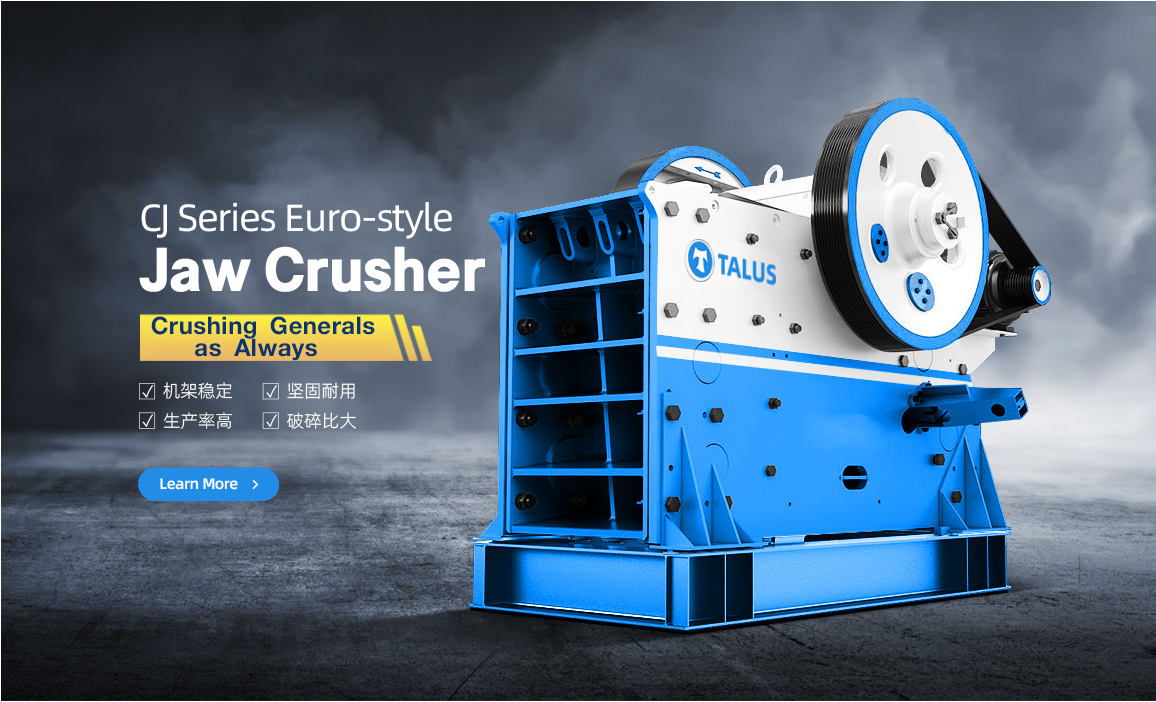

The impact sand maker mainly crushes and shapes materials through impact and collision, suitable for materials of medium hardness and brittleness. It features high efficiency, energy saving, and low production cost, and can produce sand making products with good particle shape and uniform particle size.

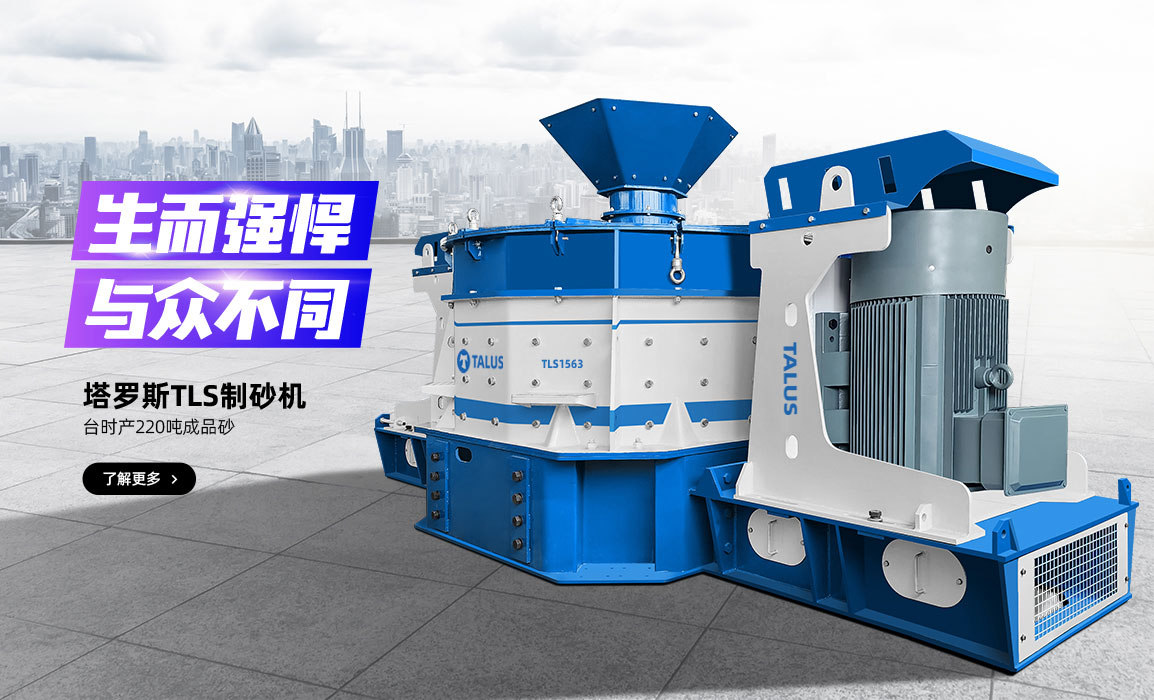

The composite sand maker combines the crushing principles of the impact sand maker and the grinding machine, suitable for materials of medium and high hardness. It has the characteristics of good crushing effect, adjustable product particle size, and strong adaptability, and can produce sand making products of different specifications as required.

Therefore, the sand making effect of the impact sand maker and the composite sand maker depends on the hardness of the material and the required specifications of the sand making product. For materials of medium hardness and brittleness, the impact sand maker may have better results; for materials of medium and high hardness, the composite sand maker may be more suitable. The final choice should be based on specific production needs and material characteristics, taking into account various factors.