With the widespread application of jaw crushers, the selection of jaw crusher accessories has become increasingly important. Because there are more and more brands and types of accessories on the market, users are also influenced by more and more factors when making purchases, making it difficult for some users to purchase suitable jaw crusher accessories.Causing a decrease in equipment productivity and a significant reduction in production efficiency is something that both manufacturers and users of jaw crushers want to avoid. So, how can one purchase suitable jaw crusher parts? What should users pay attention to when making a purchase?

1. Choose OEM-produced parts whenever possible.

OEM-produced jaw crusher parts are matched to your own jaw crusher in terms of materials, dimensions, and wear resistance. This ensures high equipment efficiency, and OEMs also offer better after-sales service.

2. Compare and select from multiple options.

Compare and analyze jaw crusher parts from several manufacturers to identify differences in price and quality. Choose the jaw crusher parts that best suit your needs. It is recommended to purchase parts from larger manufacturers as they offer better quality assurance.

3. Inspect the appearance and quality of the parts.

When purchasing jaw crusher parts, pay attention to the appearance of the parts and check for any signs of wear. Ensure that the parts are in good condition before use.

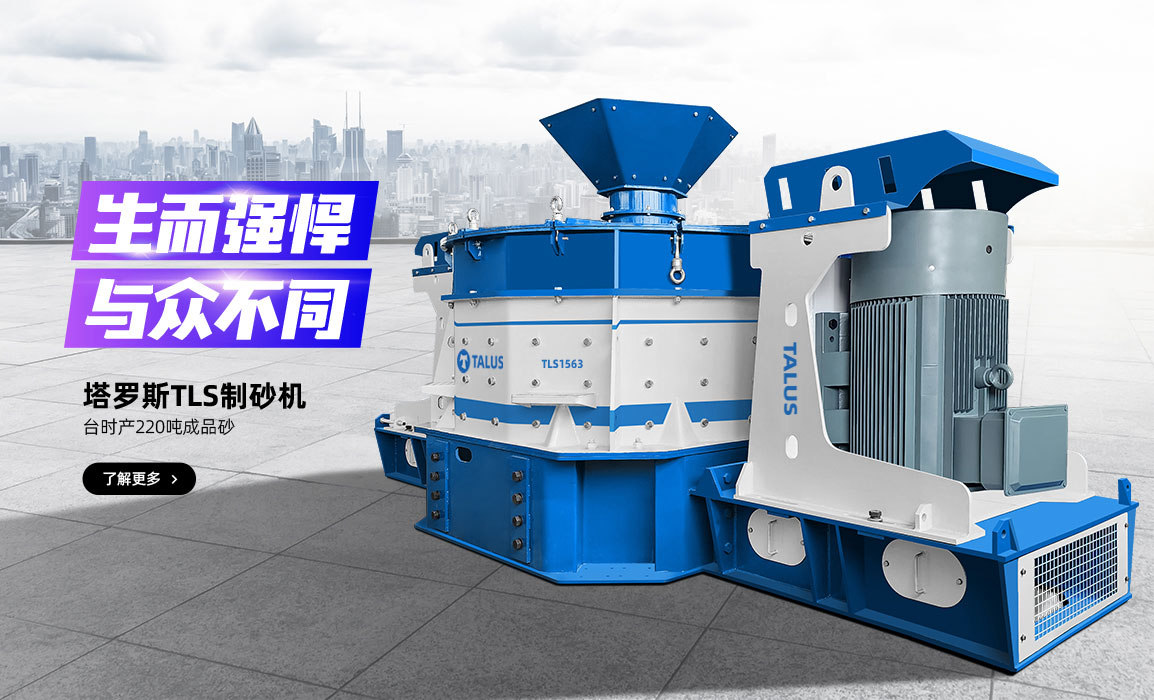

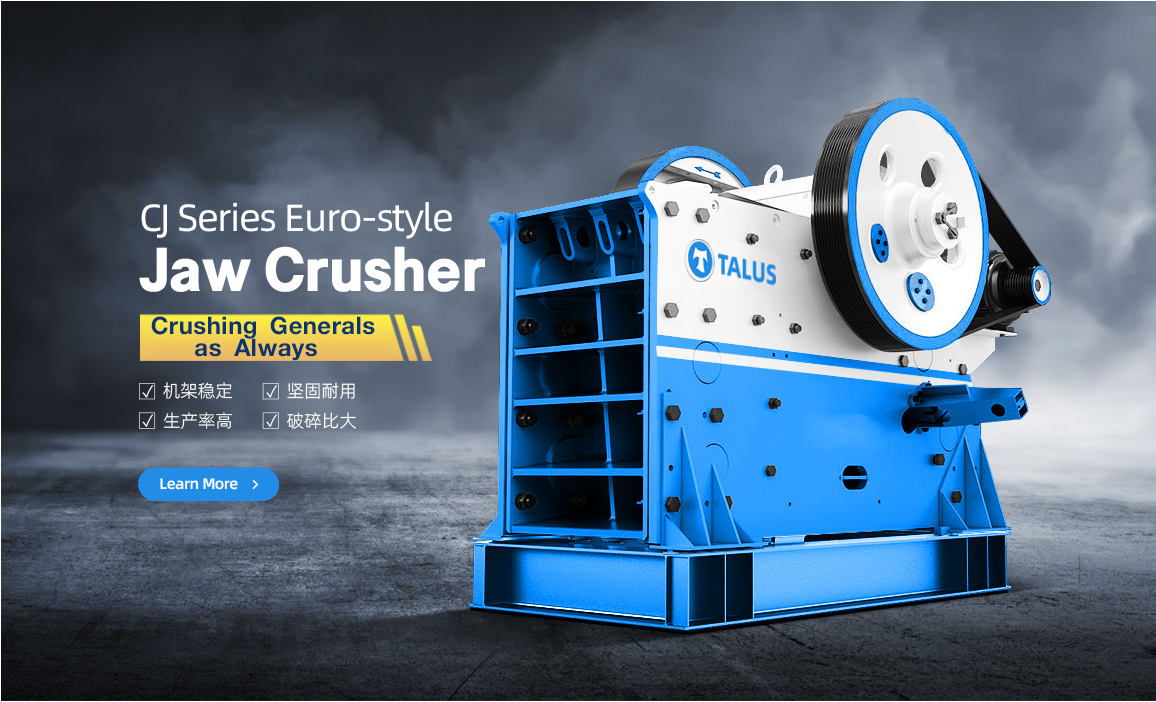

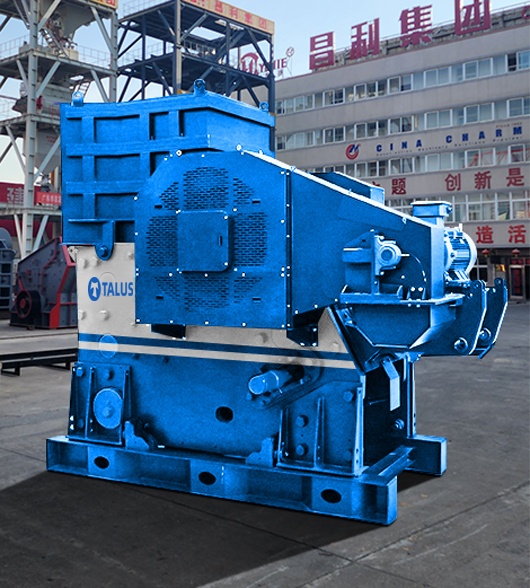

Talus Equipment focuses on the field of mining crushing and screening, as well as sand-making equipment, providing cost-effective crushing and screening solutions, mechanism sand equipment, and high-grade sand and gravel aggregate for large-scale engineering projects such as highways, chemical industry, railways, hydropower, etc.

Welcome to visit Henan Talus, the senior manufacturer of crushing and sand making.