Today, we will explain in detail about the shape of the crushing cone in cone crushers. First, we need to understand the role of the crushing cone in cone crushers. The rotation of the motor, through the pulley and the coupling, drives the transmission shaft and the cone part of the cone crusher to make a rotary swinging motion around a fixed point under the action of the eccentric sleeve. This will cause the crushing cone to approach and leave the fixed concave surface mounted on the adjusting sleeve, resulting in continuous impact, compression, and bending of the ore in the crushing cavity, achieving the purpose of crushing the ore. The motor drives the eccentric sleeve to rotate through the bevel gear, causing the crushing cone to swing. The crushing cone approaches and leaves the fixed cone, completing the crushing and discharge. The supporting sleeve is connected to the frame body and tightened by springs. When unbreakable objects such as metal blocks fall into the crusher, the spring will be compressed and deformed, ejecting the foreign objects to prevent damage to the machine.

It is suitable for crushing various ores and rocks with medium and medium-high hardness. Cone crushers have the characteristics of large crushing ratio, high efficiency, high processing capacity, low operating cost, convenient adjustment, and economical use. Users can choose different cavity types according to their needs. The sealing of the crushing cone used in this machine adopts grease seal, which avoids the drawbacks of water supply and drainage system blockage and water mixing. The spring safety system is an overload protection device that allows foreign objects and iron blocks to pass through the crushing cavity without damaging the crusher. This machine is divided into standard type and short head type. Generally speaking, the standard type has larger feeding size and coarser discharge size, while the short head type has steeper crushing cone and smaller feeding size, which is conducive to the production of fine-grained materials. Therefore, the standard type is generally used for coarse and medium crushing, while the short head type is used for medium and fine crushing.

When unbreakable foreign objects pass through the crushing cavety of the cone crusher or the machine is overloaded for some reason, the spring safety system of the cone crusher will be activated to ensure safety, and the discharge outlet of the cone crusher will be enlarged. Foreign objects will be discharged from the crushing cavity of the cone crusher. If foreign objects get stuck in the discharge outlet, the clearing system can be used to continue enlarging the discharge outlet and remove the foreign objects from the crushing cavity of the cone crusher. Under the action of the spring, the discharge outlet will automatically reset, and the cone crusher will resume normal operation. The surface of the crushing cavity is covered with wear-resistant high manganese steel liner. The size of the discharge outlet can be adjusted hydraulically or manually.

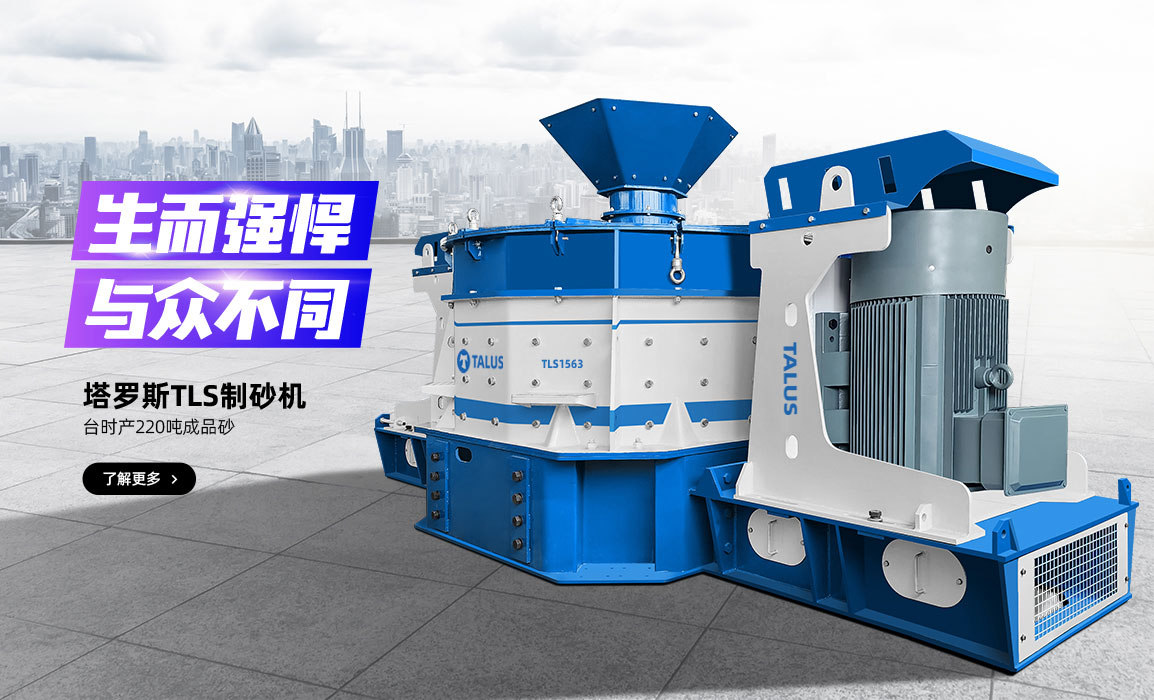

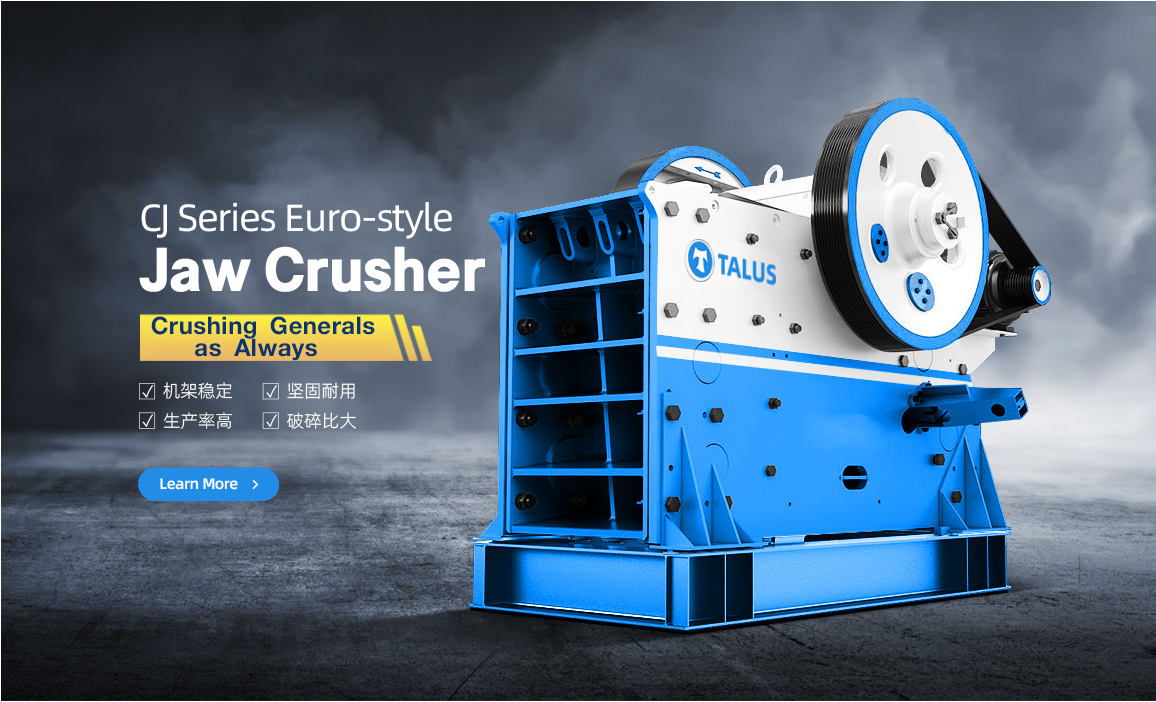

Talus Equipment focuses on the field of mining crushing and screening, as well as sand-making equipment, providing cost-effective crushing and screening solutions, mechanism sand equipment, and high-grade sand and gravel aggregate for large-scale engineering projects such as highways, chemical industry, railways, hydropower, etc.

Henan Talus Equipment, a senior manufacturer of sand making machine and crusher.