The linear vibrating screen, also known as the linear sieve, because of its good stability, low energy consumption, low noise, long service life, adjustable type and structure of screened materials, high screening output, simple structure, easy maintenance, and dehydrate materials. Therefore, it is widely used in industries such as mining, coal, smelting, building materials, refractory materials, light industry, medicine, building materials, grain, carbon, and chemical fertilizers. It mainly consists of the screen box, screen frame, screen mesh, vibrating motor, motor base, vibration damping spring, and support, etc.

1. Screen box: It is made of several steel plates of different thicknesses welded together and has a certain strength and rigidity. It is the main component of the screening machine.

2. Screen frame: It is made of pine wood or wood with small deformation and is mainly used to keep the screen mesh flat for normal screening.

3. Screen mesh: There are several types of screen meshes, such as low carbon steel, brass, bronze, stainless steel wire, etc.

4. Vibrating motor: For detailed instructions on the use and maintenance methods, please refer to the vibrating motor manual.

5. Motor base: It is used to install the vibrating motor. The connecting screws must be tightened before use, especially during the first three days of trial use of a new screening machine. They must be tightened repeatedly to prevent loosening and accidents.

6. Vibration damping spring: It prevents vibration from being transmitted to the ground and supports the weight of the screen box. When installing, the spring must be perpendicular to the ground.

7. Bracket: Composed of four pillars and two channel steels, it supports the screen box. During installation, the pillars must be vertical to the ground, and the channel steels under the two pillars should be parallel to each other.

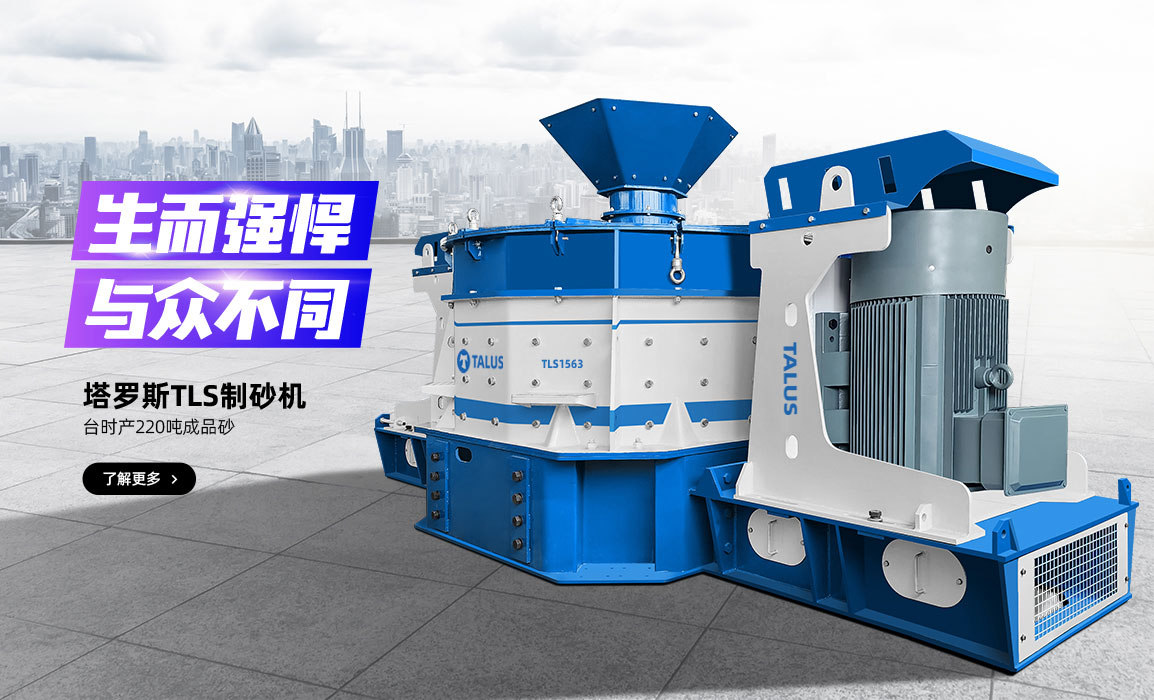

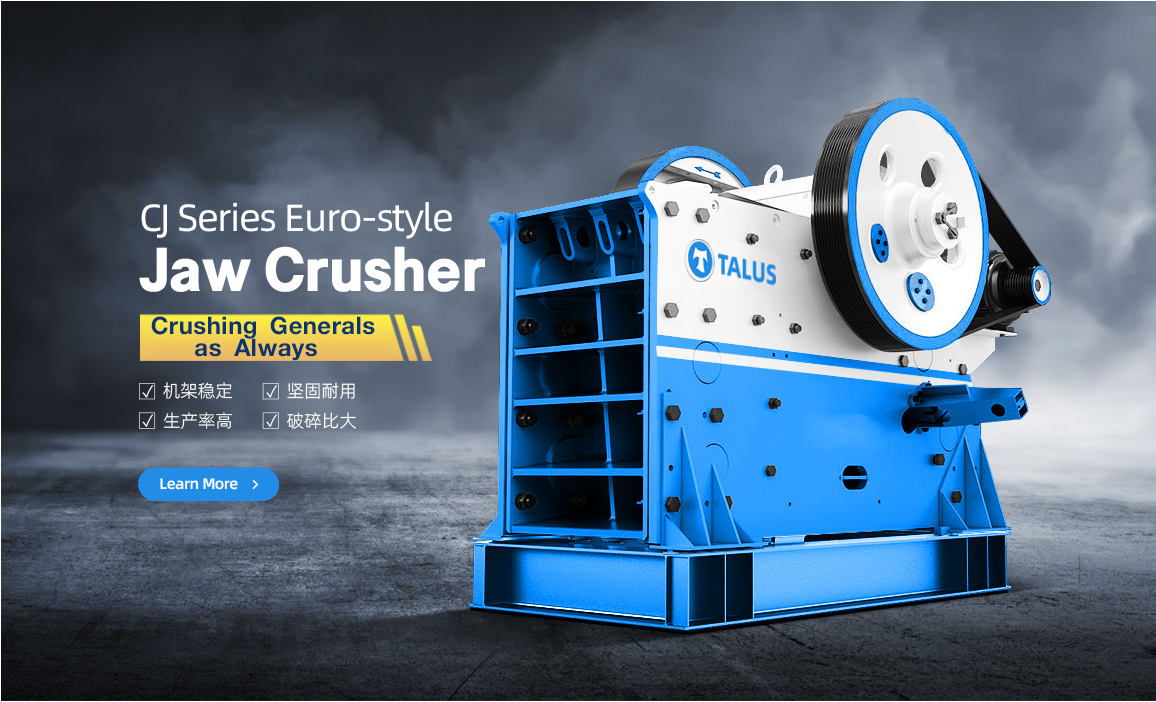

Talus Equipment focuses on the field of mining crushing and screening, as well as sand-making equipment, providing cost-effective crushing and screening solutions, mechanism sand equipment, and high-grade sand and gravel aggregate for large-scale engineering projects such as highways, chemical industry, railways, hydropower, etc.

Talus Equipment specializes in the production of sand making machine.