Cone crusher is one of the widely used mining machinery equipment. With the development of the market, there are various types of products domestically, but the performance varies. Here is an analysis of the characteristics of five mainstream equipment to help you choose the right one!

1. Simmons Cone Breaker

Due to its low price, relatively stable performance, and widespread user experience in use and maintenance, the Simmons cone crusher can be used as a medium or fine crusher in situations where the product particle size is not high. It is currently the most commonly used cone crusher in the world.

Since the Simmons cone crusher controls product particle size by reducing the size of the discharge opening, this machine is not suitable for use as ultra-fine crushing or sand making.

In addition, the force on the main shaft of this machine is a cantilever beam, which makes its structure much heavier than a single-cylinder hydraulic cone crusher of the same specifications. It also has a small crushing force, low output, and unreliable iron protection function. This machine will gradually be updated by high-energy interparticle crushing type, and replaced by the hydraulic cone crusher. Domestic manufacturers have added a hydraulic cavity cleaning function to this type of crusher, which is called a composite type.

2. Rotating disc cone crusher

The rotary disc cone crusher is launched by Nordberg Company and is suitable for the fourth stage of crushing of medium-hard materials. It is characterized by its special crushing cavity shape, which can achieve lamination crushing and obtain a smaller product particle size under large discharge openings. For example, when the closed-side discharge opening is 12mm, the product content with particle size below 5mm accounts for about 50% (depending on the equipment), so it is often called an ultra-fine crusher. Since the product particle size and particle shape of the rotary disc cone crusher are relatively good, it can not only provide finer-grained raw materials for the mill but is also an effective equipment for artificial sand making. The disadvantages of this machine are high energy consumption, bulky machine and low output. With the development direction of cone crushers becoming increasingly high-energy, this machine will gradually be replaced by hydraulic cone crushers. The bottom single-cylinder hydraulic cone crusher represented by the CH series has a simple structure, low manufacturing cost, and stable performance. It is suitable for medium, fine, and even ultra-fine crushing operations.

3. Single Cylinder Hydraulic Cone Crusher

The characteristics of the single cylinder hydraulic cone crusher are a steep cone, high swing frequency, and small eccentric distance. It adopts a main shaft simply supported beam support form, with a bottom single cylinder hydraulic support and a top star-shaped frame structure. The overall structure is simple, the appearance is beautiful, and it is easy to be automatically controlled. In addition, the dynamic cone has a large supporting spherical radius R, a small eccentric angle of the main shaft, and a deep crushing chamber, which improves the uniformity of the crushed material. The product has a uniform particle size, less needle-like material, and small fluctuation in crushing force and power.

However, the crushing force of the single cylinder hydraulic cone crusher is slightly insufficient, especially for crushing hard materials. Due to its adjustment method of lifting the dynamic cone, the wear of the concave surface of the cone is uneven when the feeding is uneven. Also, the hydraulic cylinder is located at the bottom, resulting in a small working space at the bottom and bringing certain difficulties for maintenance.

4. Multi-Cylinder Hydraulic Cone Crusher

The characteristics of the multi-cylinder hydraulic cone crusher are high swing frequency, large eccentric distance, and gradual cone. It adopts peripheral multi-cylinder hydraulic locking, and the main shaft is supported by a cantilever beam and a spherical tile support structure. It uses a hydraulic motor to adjust the fixed cone, and it has a high crushing force, suitable for crushing hard materials. However, due to the smaller spherical radius R, the rotating radius is smaller, resulting in unstable phenomena such as dynamic cone oscillation, overturning, and flying cars. There are also problems such as poor contact between the main shaft and the bushing and large impact force, which affect the normal operation of the machine. However it has a high processing capacity, and materials smaller than the discharge outlet can even account for 70% to 80% of the processing capacity.

Taking the HP series multi-cylinder hydraulic cone crusher as an example, it has the characteristics of high crushing force, high swing frequency, high production yield, good product granularity and shape. It can be used for medium crushing, fine crushing, and ultra-fine crushing, and it has a good crushing effect. Since 2000, some domestic manufacturers have digested and absorbed the HP300 and HP500 multi-cylinder machines. Although the price is relatively lower, the performance is not stable, the failure rate is higher, and there is a significant difference compared to the superior HP.

Analysis of single-cylinder and multi-cylinder hydraulic cone crushers:

Overall, the multi-cylinder hydraulic cone crusher has better crushing performance. It has a greater crushing force and crushing ratio, and a wide range of discharge adjustment, providing greater flexibility in adjusting product gradation. It is superior to the single-cylinder cone crusher in terms of performance and crushing product quality. However, whether to choose a single-cylinder or a multi-cylinder crusher depends on the layout of the entire process.

If a higher crushing ratio is required, a multi-cylinder hydraulic cone crusher can be used to reduce the number of crushing stages and lower system investment. The needle-like content is generally below 15%. If crushing hard rocks, a multi-cylinder hydraulic cone crusher can be selected. If crushing general rocks, a single-cylinder hydraulic cone crusher can be chosen.

5.Inertial cone crusher:

The crushing principle of the inertial cone crusher is unique. It is a new type of ultra-fine crushing equipment with a good "layered crushing" effect. The crushed product has a millimeter-level particle size, which meets the requirements of the new "more crushing and less grinding" process, greatly reducing the energy consumption and steel consumption of the crushing and grinding process. Currently, the inertial cone crusher is still in the stage of application, improvement, and development. It can achieve very fine particle size and has a large crushing ratio. It is better for ultra-fine crushing or artificial sand making compared to other types of cone crushers. However, this machine also has its drawbacks, such as being too heavy, with a weight approximately twice that of other cone crushers.

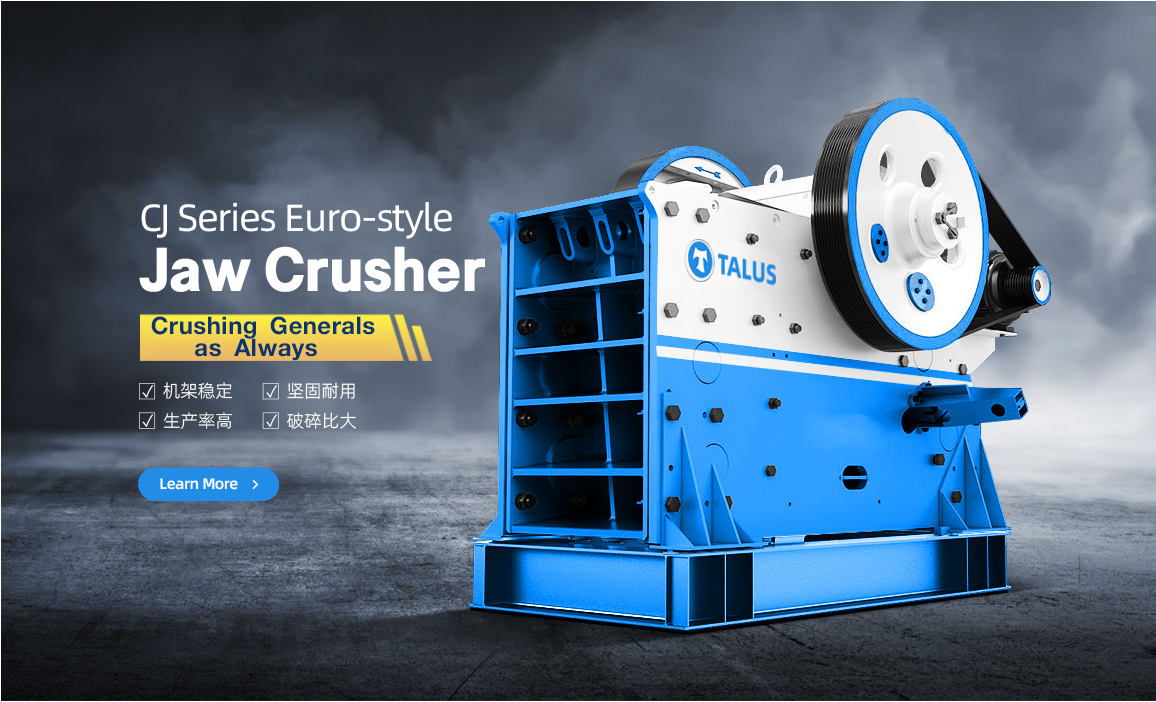

The performance comparison and characteristics analysis of various types of cone crushers mentioned above can be used as a reference for equipment selection. Of course, after determining the equipment type, specific specifications, dimensions, and quantities should be selected based on the configuration with other equipment and the variation of load rate to achieve the expected production goals. If you are looking for a good cone crusher, please consider Henan Talus Equipment. We are a professional crusher manufacturer. For bosses who need it, please feel free to contact with us.