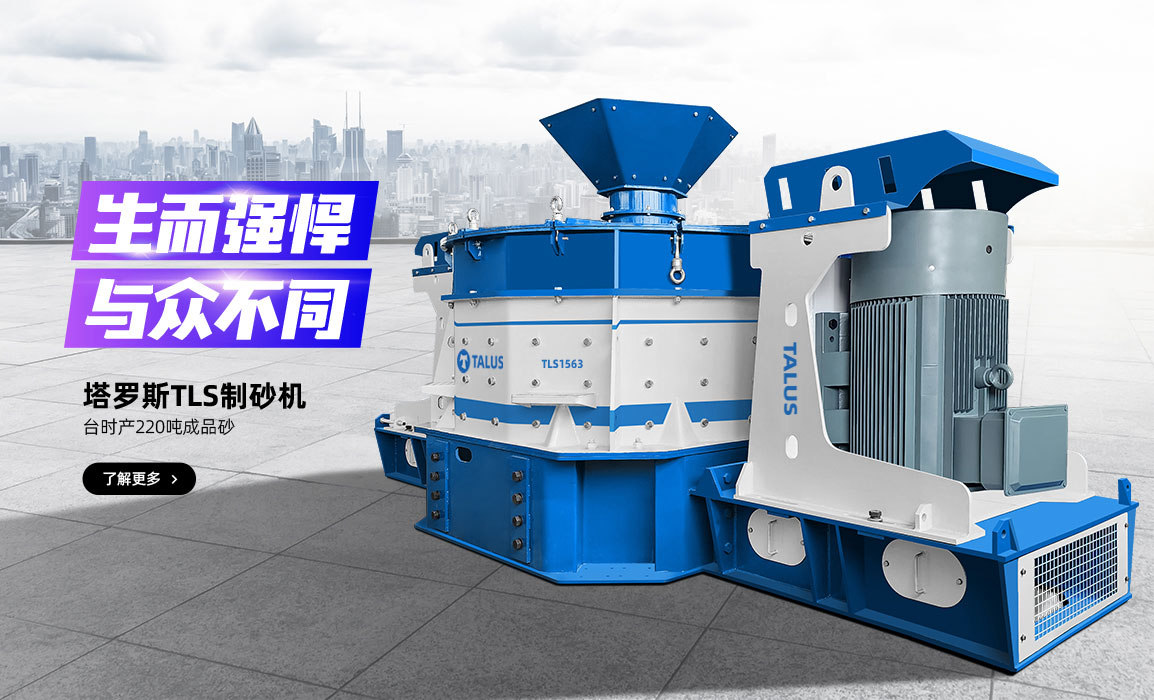

Talus Sand Making Machine

Equipment Introduction

TLS sand maker is a new type of vertical shaft impact crusher independently developed by Henan Talus Equipment Manufacturing Co., Ltd. originated from ingenuity of Belgium famous industrial designer Talus. It is a new type of sand making and reshaping equipment with stronger processing capacity, higher sand shaping rate and lower maintenance cost, which is developed by adopting new design concepts and new materials and techniques in the world.

Material handling capacity

490 tons/h

Rate of one-time sand shaping

75%

Motor power

315+315(kw)

Reinforced spindle structure design with stronger load-bearing capacity

The optimized design of central axis module adopts a specially designed dust-proof and sealing structure, and equipped with imported bearings from the United States, which has stronger load-bearing capacity, and solves the risk of traditional sand making machine being prone to spindle breakage or shaft breakage during over load operation, and ensures a higher stability and safety.

Intelligent control of diluted oil lubrication system

Adopting diluted oil lubrication and equipped with air-cooling system, controlled by PLC and intelligent meter, it can realize fully automatic lubrication control, the lubrication temperature can be adjusted and controlled. If there is a high oil temperature or oil shortage, the system will be automatically shut down, which can provide more reliable protection for operation of bearings.

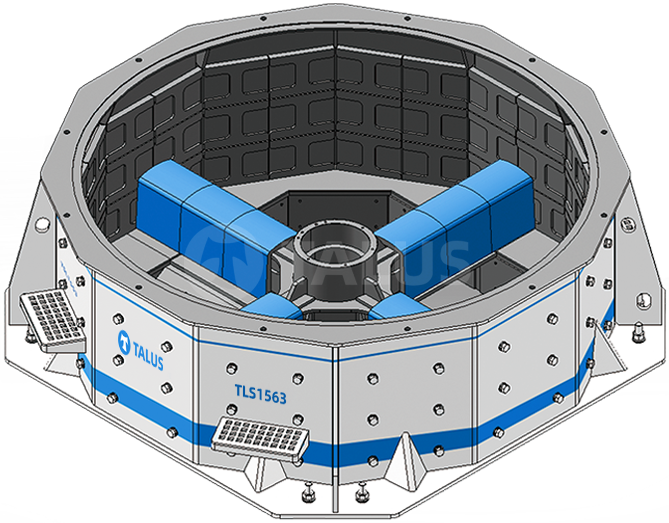

1.5m Wide rotor diameter and six

channel throwing ports design

channel throwing ports design

The diameter of the machine rotor is up to 1.5 meters, and inside of the rotor has a more spacious passing space, which can accommodate more materials to enter. Adopting six channel throwing ports, under the action of centrifugal force of the rotor's high-speed rotation, more materials can be instantly thrown into the circular liner plate or material layer in the crushing cavity, which realizes a greater throughput, higher production efficiency, and better quality of cubic products.

Double discharge ports design enables non clogging production

Double discharging ports design improves throughput of materials, smoother discharging, and greatly reduces the risk of material clogging. For materials with excessive humidity, air cannon system can be installed for the sand maker if necessary to minimize the bonding of materials in the discharging area.

Product show

Every detail has been deliberately considered, from the exterior design to the internal structure.

Technical Parameter

Multiple types available, there is always suitable one for you.

| Model |

Rotor diameter×height (mm) |

Circumferential Speed (m/s) |

Drive power (kw) |

Throughput rate (t/h) |

Max Feeding size (mm) |

|---|---|---|---|---|---|

| TLS1563D (Dual drive) |

1500×220 | 70~80 | 315+315 | 100~490 | ≤50 |

| TLS1563S (single drive) |

1500×220 | 70~80 | 450 | 100~490 | ≤50 |

| TLS1040S (single drive) |

1000×220 | 70~80 | 400 | 100~300 | ≤50 |

More Device Recommendation

Perhaps you still need these devices recommended.

CLV Vertical Shaft Impact Sand Making Machine

PFL Vertical Compound Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

HP Multi Cylinder Hydraulic Cone Crusher

Please submit your request for a detailed product quotation