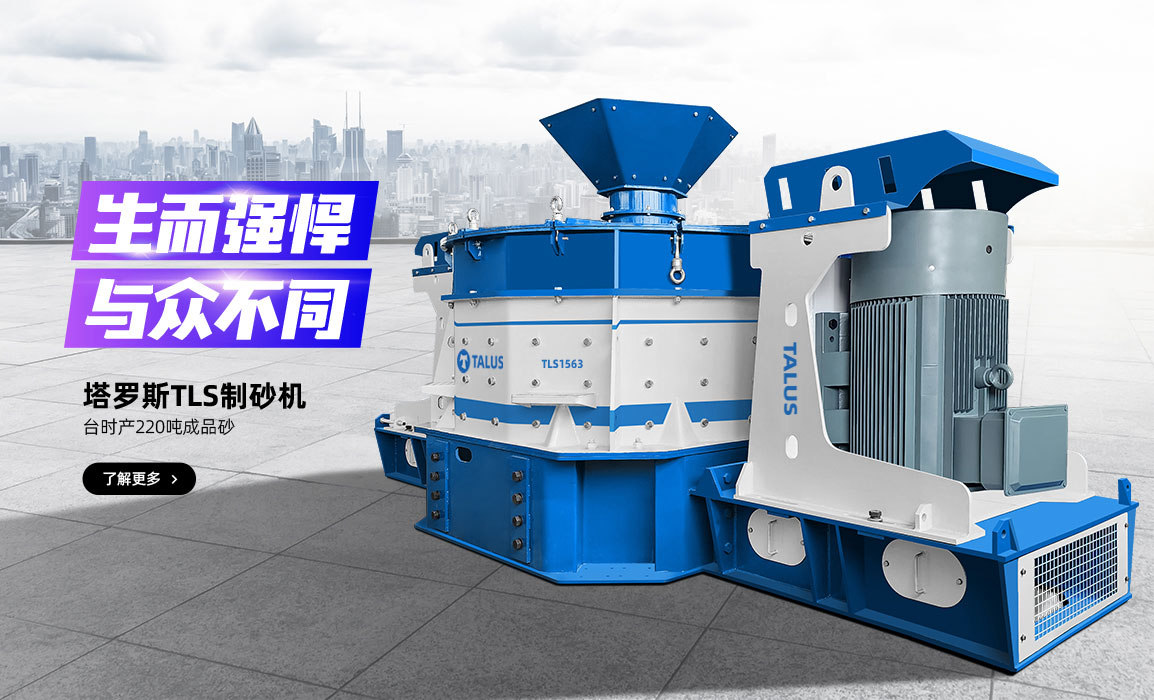

Product Introduction

TSL series environmentally friendly modular sand making plant is a high-grade dry mechanism sand production system independently developed by Henan Talus Equipment Manufacturing Co., Ltd. It adopts highly intensive tower like fully enclosed arrangement, integrating sand making, optimized reshaping, grading adjustment, stone powder control, water content control, and environmental dust-proof, which not only saves space and improves production efficiency, but also meets the production requirements of various granularity and particle sizes, and increases the proportion of fine sand with particle sizes between 2.36-0.6mm which is used in concrete and dry mixed mortar, and improves performance indexes such as granularity, grading, and ratio of powder content and so on, which can greatly meet requirement for high-quality mechanism sand for various kinds of concrete and dry mixed mortar.

Technical characteristics

Intensive design with small footprint

It can be individually designed according to customer's own site conditions, adopting a tower layout. The production process is completed from top to bottom, including crushing, sand making, screening, powder selecting and humidifying etc. The compact structural design saves space and reduces the construction site footprint, which saves a lot of land costs and infrastructure costs.

Modular design for more convenient installation

All modules are factory pre-fabricated and assembled according to the real proportion of customer site, allowing for trial production in factory. The modular design shortens on-site installation time and is easy to dismantle and reinstall, ensuring that the project can be quickly relocated and reassembled according to construction requirement.

High quality of finished sand with more reasonable gradation

Tower like sand making system adopts Talus dual power sand maker independently developed by Henan Talus Equipment Manufacturing Co., Ltd., which has stronger crushing and stone reshaping capabilities, and the output of finished sand particles is full, rounded surface, uniform particle distribution, and the grading, granularity and powder content of the sand are more reasonable. The proportion of 0.15-0.6mm fine sand is greatly increased, while the proportion of 2.36-4.75mm coarse sand is decreased, and the powder content is between 3-15%, which can be adjusted in a wide range.

High environmental protection standards, meet requirement of environmental protection standards.

Tower like sand making system adopts design of a fully enclosed conveying, production and negative pressure dust-proof . The fully enclosed structure achieves dust emission concentration at production site reaches the national environmental standards. The negative pressure dust collector, combined with the sealing operation in a fully enclosed environment throughout the entire process, ensures that there is no dust at the site during the whole conveying process from powder ore silo to powder tank trucks, while dry processing does not require water washing, and there is no sewage and silt disposal problem during the production. In addition, the main tower can be packed according to customer requirements, while also achieving dust-proof and noise reduction effects. All environmental indicators of the entire tower like sand making system meet requirement of national environmental protection standards.

More intelligent system, high degree of automation.

Through a centralized control system or PLC automatic control system, it can realize on-line real-time monitoring of the production status of the equipment, adjusting the operation of the whole set of equipment, one-key start-stop, abnormal alarm, emergency shutdown, automatic stabilization of the operating parameters, etc., which can ensure the quality of the finished sand and the production line production capacity smooth and stable, as well as the production of each production link is safe, stable and sustainable.

Process flow and operation principle of tower like sand making plant

TSL Tower Like Sand Making Plant is a tower style sand making system adapting dry processing technology, which is mainly consists of a loading material conveying system, sand reshaping and screening system, dust-proof system, stone powder storage system and electrical control system. Raw materials are fed into the top floor through bucket elevator, and 0-60mm crushed stones are fed into Talus sand maker through a raw material conveyor belt. After high-frequency stone-on-stone grinding, it is delivered to stone powder separation room. The sand powder content is adjusted by adjusting size of air inlet of powder control box and system air volume. The processed material enters separating screen to separate out the fine crushed stones, stone powder and quasi-products of sand. The stone powder is collected as fine stone powder after being processed by dust-proof and dust collection system, and the quasi-products of sand is evenly mixed by humidifying mixer, which is fine mechanism sand.

3D rendering of tower like sand making plant

Multi-angle display, please make an appointment to visit the physical factory.

Performance parameter

remark: The output will vary depending on factors such as different feeding materials or particle size.

| Model | Sand maker type | Vibrating screen | Max. feeding size | Processing capacity | Stone powder content | Control system |

| TSL220 | TLS1553 | 2YK3070 | ≤60mm | 220t/h | 3-15% controllable | PLC control or centralized control |

| TSL160 | CLV1263 | 2YK2460 | 160t/h | |||

| TSL60 | CLV1145 | 2YK2160 | 60t/h |

Project on Site

More than 40 years of specializing in sand making equipment, a common choice for over 500000 customers worldwide.

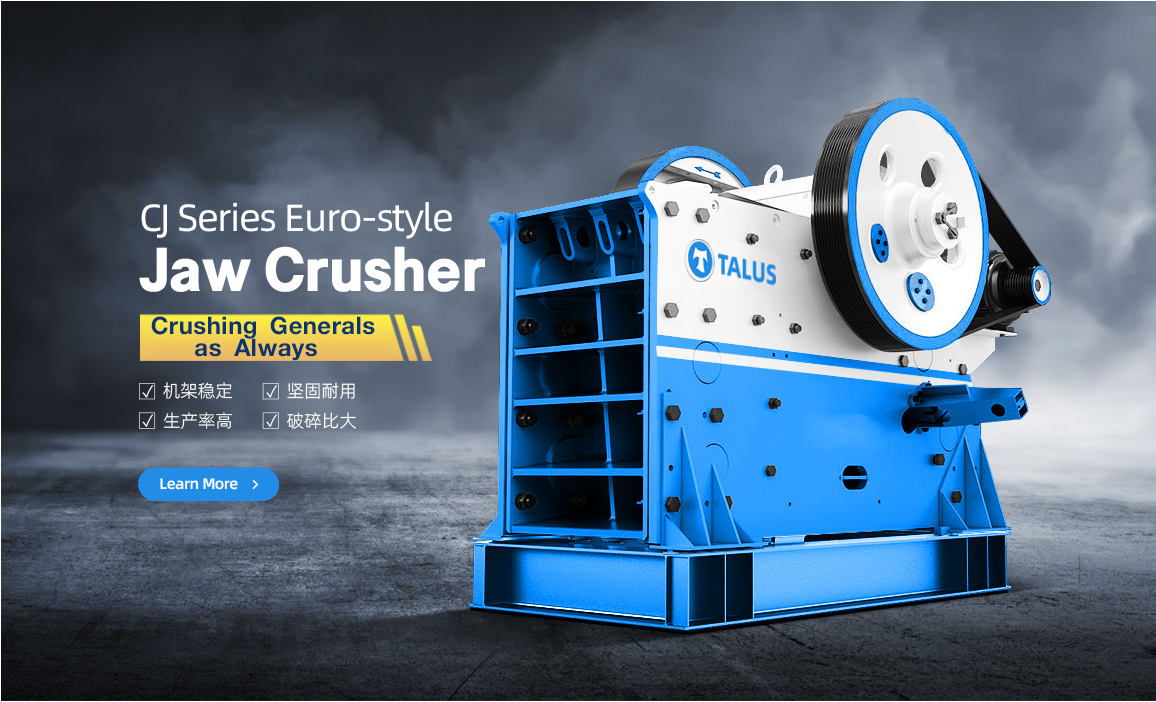

More Device Recommendation

Perhaps you still need these devices recommended

Talus Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

PFL Vertical Compound Sand Making Machine

CLV Vertical Shaft Impact Sand Making Machine

Inclined Vibrating Screen

Vibrating Feeder

Please submit your request for a detailed product offer